Industrial Design

People always ask: what does an industrial designer do? Or, what is industrial design? In a nutshell, it’s the process of designing products that can be manufactured through mass production. Any type of product, from a paper clip to a motorcycle, or from a cell phone case to an airplane, has had an industrial designer involved in its production. Anything you can possibly imagine can be conceptualized, designed, and developed by an industrial designer.

1 905-833-5122

Because every manufacturing process varies, the design process also varies from one product to the other. When designing different products, industrial designers always generate prototypes for user and ergonomics testing. For every product an industrial designer develops, the design process will change based on factors like size, material, and the number of parts of an assembly. Here are a few examples of different items and the varying design processes involved.

Industrial design for small products or single-part products

One-part products are very common and the simplest ones to design. They don’t have to undergo any mechanical tests and—most importantly—they are not part of any assembly. For these products the industrial designer usually creates some concept sketches to define the overall shape and form. Once renderings are approved, the prototype is printed in a 3D printing machine. If proportions and forms are nicely generated and functioning properly, the part is ready to tool up and head to production.

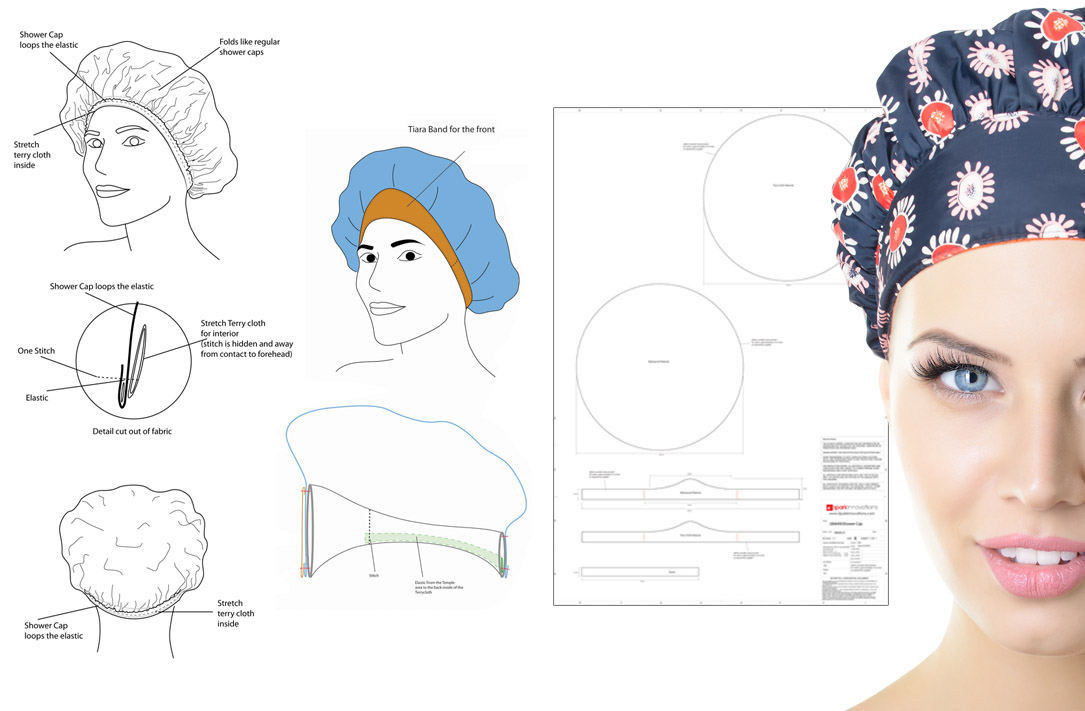

Industrial design for products made of fabric

For products made of fabric, industrial designers create concept sketches to define the overall shape and form. After these sketches are approved, products made of fabric are straightforward to design because the prototype can be made in a very rudimentary way. Patterns for manufacturing can be sewn and cut by hand or machine and alterations can be made without having to fabricate the entire prototype again. With the patterns in-hand, an industrial designer can create a functioning prototype for presentation purposes from the proposed materials. If these prototypes are ready to go, they can be sent to production.

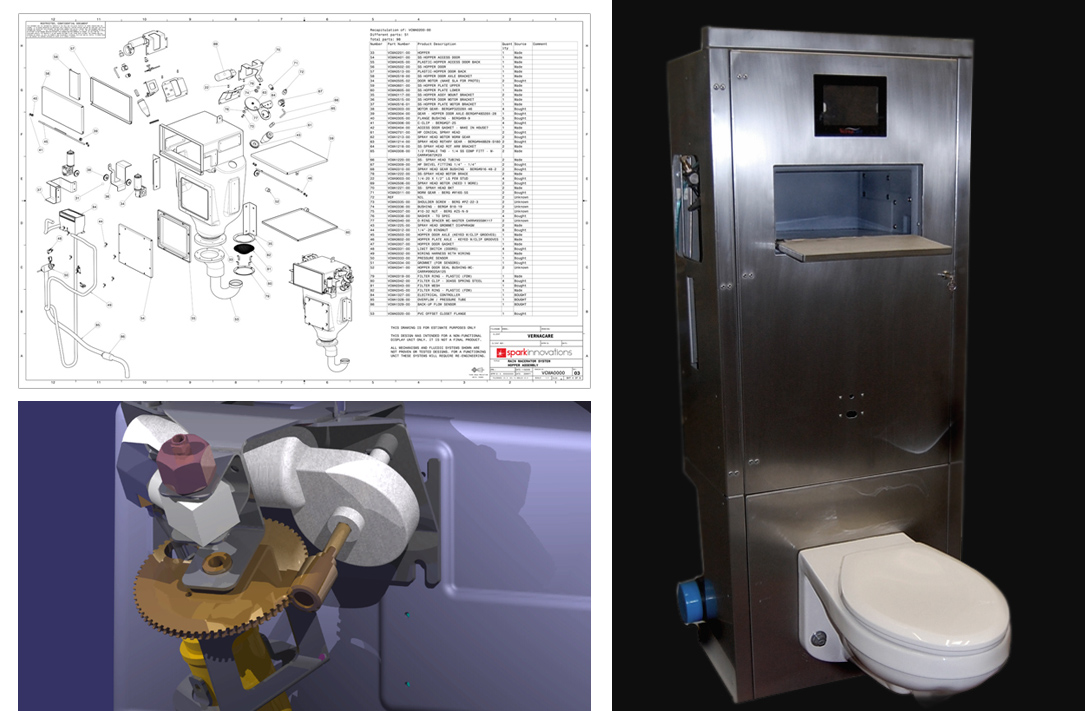

Industrial design for large assemblies

Assemblies or products that are composed of several parts are common. With assemblies, many details have to be attended to when preparing for production. Such products have to undergo mechanical tests. Details like tolerances and material selection have to be considered as part of any assembly. 3D programs are vital for evaluating these specifics and they also help the industrial designer with the communication that is needed when a product is ready for manufacturing. Every part of the prototype is 3D printed. If proportions and forms are working correctly, the part is ready to tool up and head to production.

These are just a few examples of the design processes the industrial designers at Spark Innovations use to transform ideas into a physical product ready for manufacturing.

Recent Comments