Prototype Objectives

Prototype objectives refer to the specific goals and aims you want to achieve when developing a prototype of a product, system, or idea. The objectives for creating a prototype can vary depending on the project and its specific needs, but they generally fall into several common categories:

- Proof of Concept

- Functionality Testing

- User Experience (UX) Testing

- Feedback Gathering

- Risk Mitigation

- Cost Estimation

- Performance Testing

- Iterative Development

- Market Validation

- Stakeholder or Investor Communication

- Regulatory Compliance Testing (If possible)

Prototype Processes

There are many different processes available to make prototypes. Choosing the right combination of processes for a prototype is crucial to a successful project. Many factors affect the choice of process, like cost, speed, quality, functionality, longevity. Below are some of the processes available to us at Spark:

- 3D printing

- CNC Machining

- Metal Casting

- Rubber casting

- Vacuum Casting

- Sewing

- Extrusion

- Low volume molding

- Stamping

- Sheet-metal forming

Prototype Processes

There are many different processes available to make prototypes. Choosing the right combination of processes for a prototype is crucial to a successful project. Many factors affect the choice of process, like cost, speed, quality, functionality, longevity. Below are some of the processes available to us at Spark:

- 3D printing

- CNC Machining

- Metal Casting

- Rubber casting

- Vacuum Casting

- Sewing

- Extrusion

- Low volume molding

- Stamping

- Sheet-metal forming

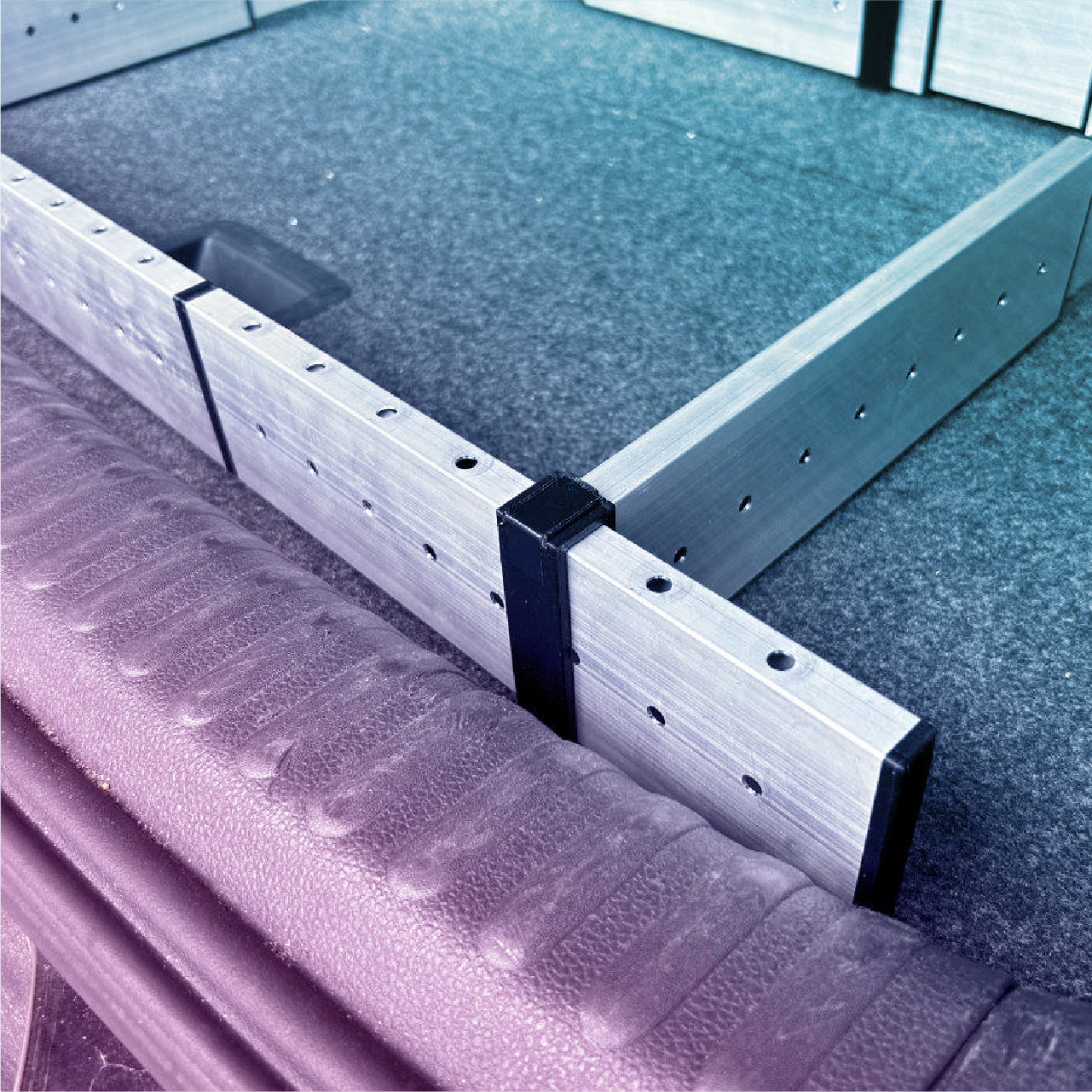

Assembly & Testing

Assembling and testing prototypes is just as important as making the parts. Troubleshooting, iterating, testing, validating and implementing changes are all crucial in getting everything out of a prototype and moving the project forward.

Assembly & Testing

Assembling and testing prototypes is just as important as making the parts. Troubleshooting, iterating, testing, validating and implementing changes are all crucial in getting everything out of a prototype and moving the project forward.

3D Printing

The most obvious advantage of 3D printing is cost and turnaround time, 3D printing allows for very quick iteration development. Spark has in-house 3D printing services as well as outsourced established channels for every 3D printing process available.

3D Printing

The most obvious advantage of 3D printing is cost and turnaround time, 3D printing allows for very quick iteration development. Spark has in-house 3D printing services as well as outsourced established channels for every 3D printing process available.

3D Printing

Quality, cost, durability, intended material, and prototype strategy all play a part in choosing the right process and material for a prototype. Plastics, metals, and soft materials are all available in this process. There are many different 3D printing technologies like FDM, SLA, MSLA, SLS, MJF, Polyjet…

CNC Machining

This process yields high quality parts, it can produce smooth plastics, transparent materials, high gloss, painted, and durable prototypes. The costs are higher than 3D printing but the quality can be very good.

CNC Machining

This process yields high quality parts, it can produce smooth plastics, transparent materials, high gloss, painted, and durable prototypes. The costs are higher than 3D printing but the quality can be very good.

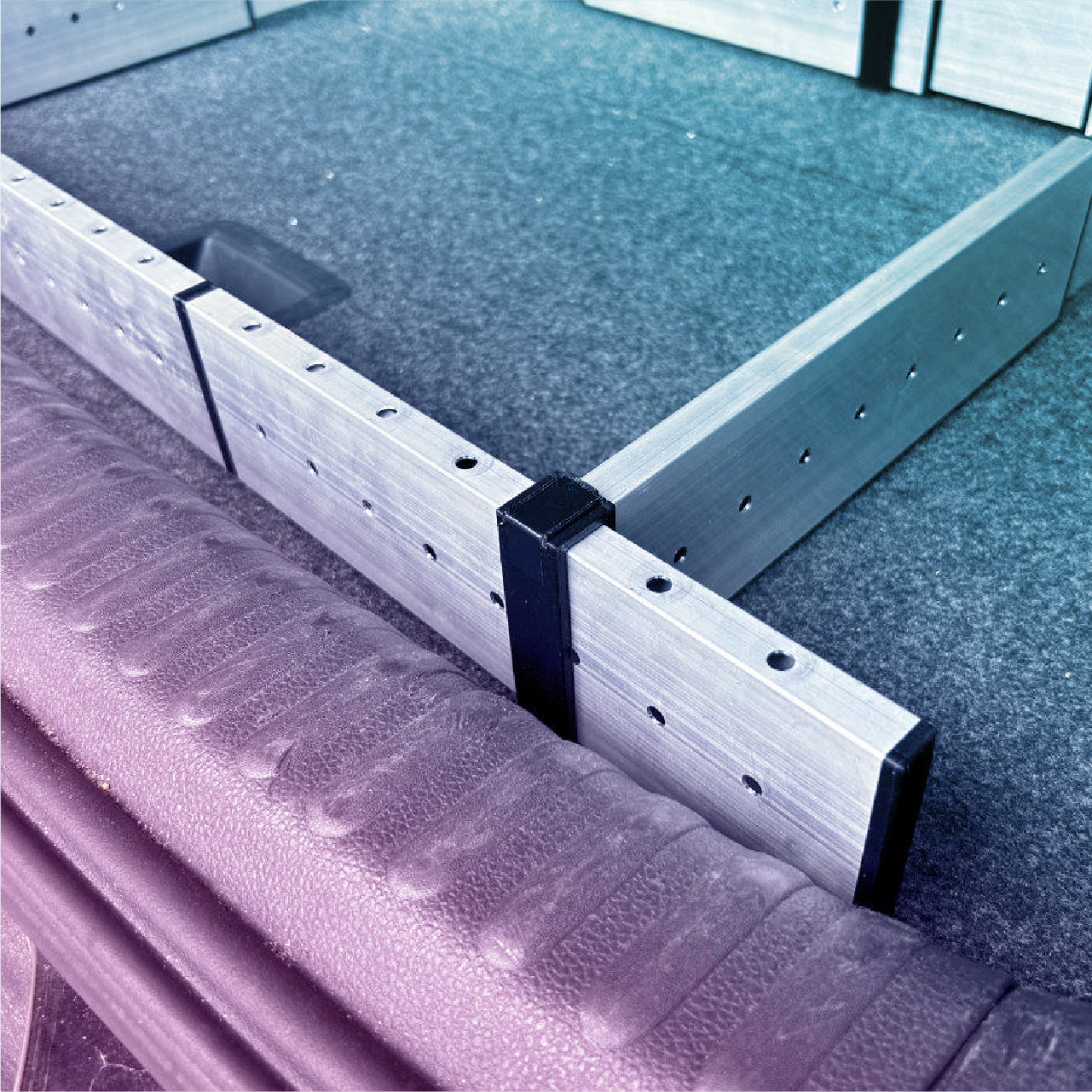

Sheet-metal Forming

Sheet-metal parts are great for making parts that need to withstand forces and can essentially be production quality parts. Welding, powder coating, machining, bending are all processes that are used with sheet metal prototyping.

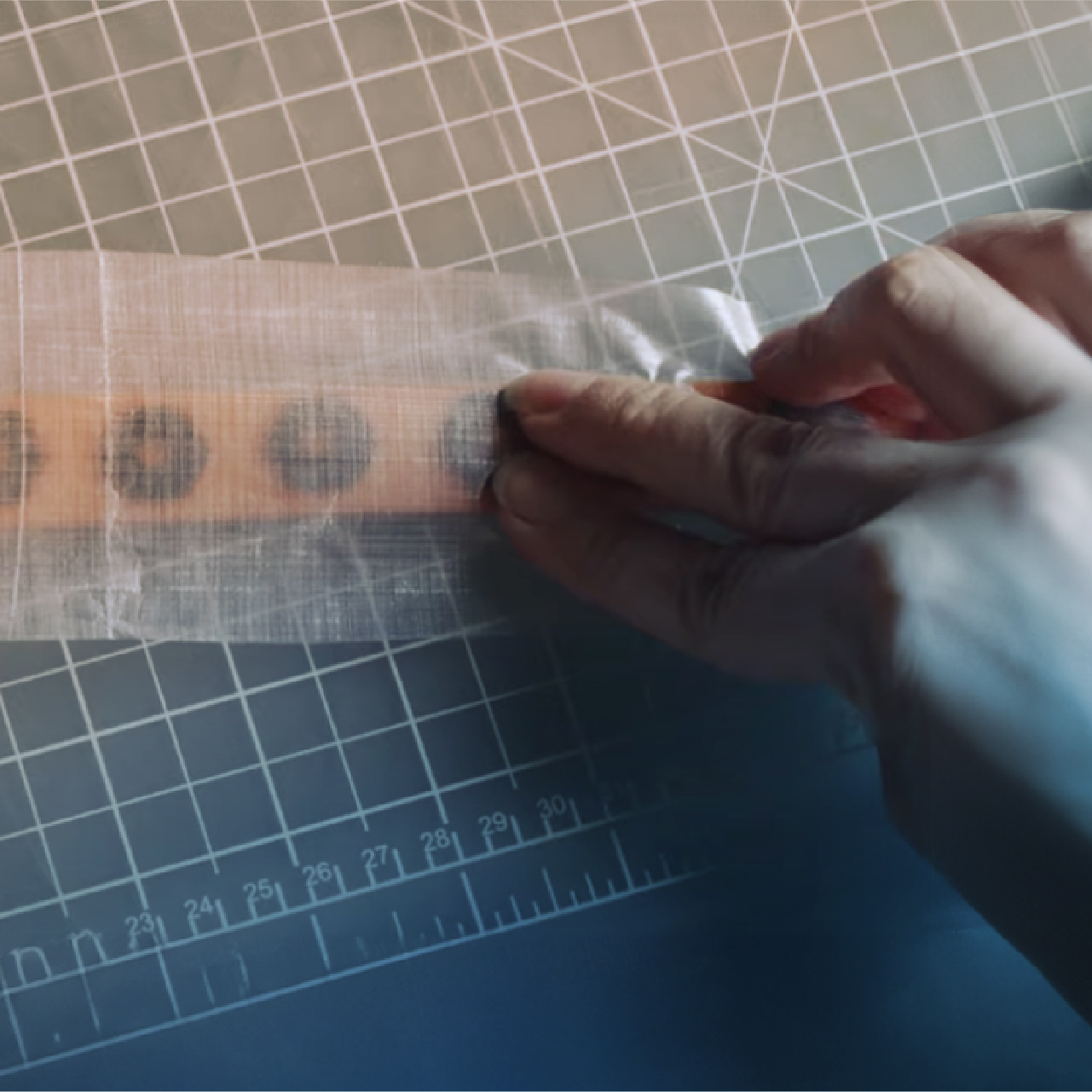

Sewing

Sewing is a great strategy for prototyping, it requires sewing templates and a great working relationship with a prototype seamstress.

Sewing

Sewing is a great strategy for prototyping, it requires sewing templates and a great working relationship with a prototype seamstress.

Vacuum Casting

Vacuum casting, also known as urethane casting, is a manufacturing process used to create high-quality, detailed, and functional prototypes or small production runs of parts or products. It’s an excellent choice when high-quality prototypes or small production runs are needed.

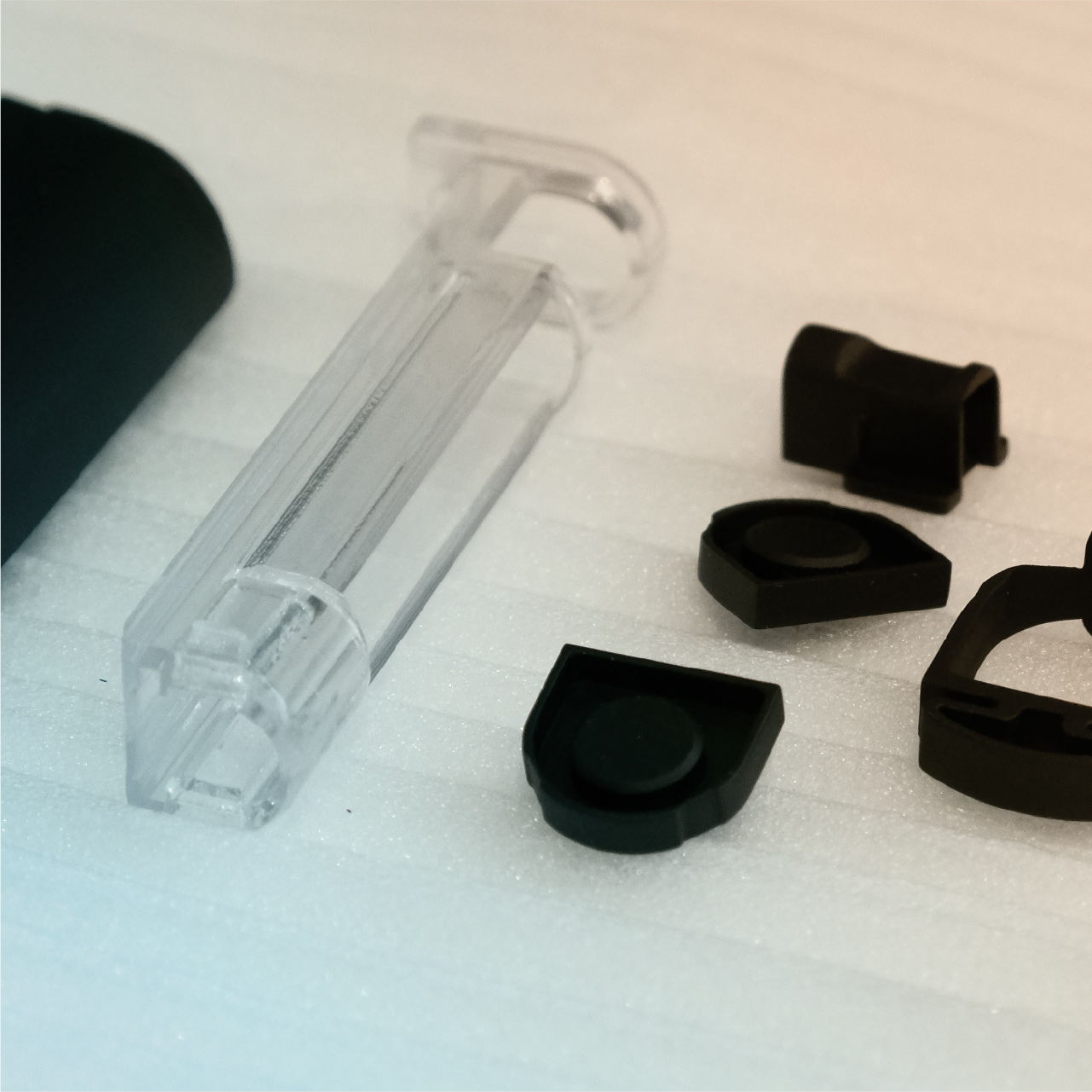

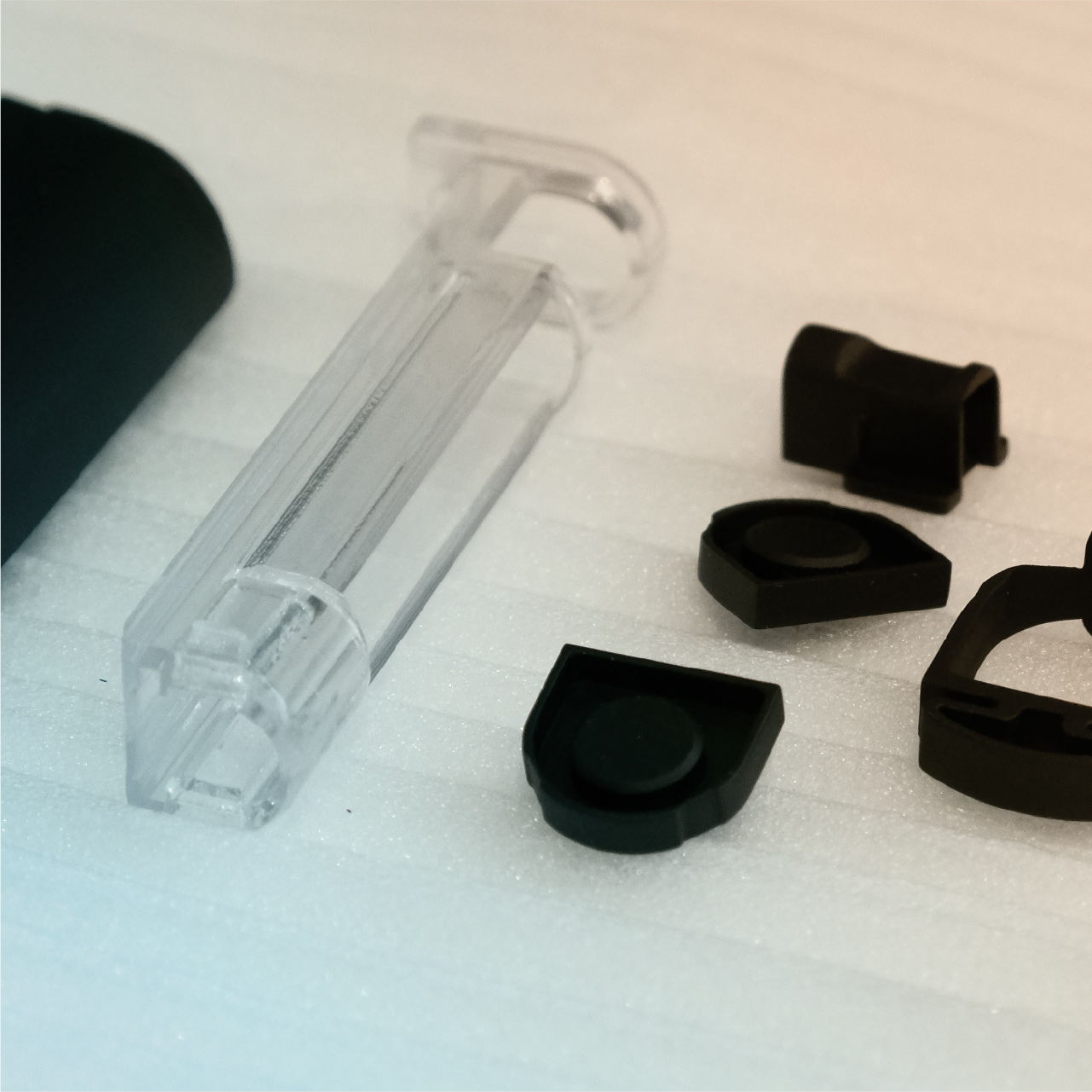

Urethane Casting

Urethane casting is used for soft materials like, silicone, rubber, urethane, polyurethane. It’s great for testing material properties and the quality can be as good as production parts.

Urethane Casting

Urethane casting is used for soft materials like, silicone, rubber, urethane, polyurethane. Its great for testing material properties and the quality can be as good as production parts.

Metal Casting

Metal casting is a production process that can be used to make prototypes, the tooling can be cost effective and therefore a good strategy for parts that need validation testing, strength and longevity.

Extrusion Process

The extrusion process, for both plastics and metals, is a final production process that can be so cost effective that it can be utilized for prototyping . The tools used for the prototypes can be used for production

Extrusion Process

The extrusion process, for both plastics and metals, is a final production process that can be so cost effective that it can be utilized for prototyping . The tools used for the prototypes can be used for production