Design for Manufacturing

Design for Manufacturing (DFM) is an approach that focuses on designing products and components in a way that makes them easier and more cost-effective to manufacture. It involves considering manufacturing processes, materials, and assembly methods during the design phase to optimize for efficiency, quality, and cost

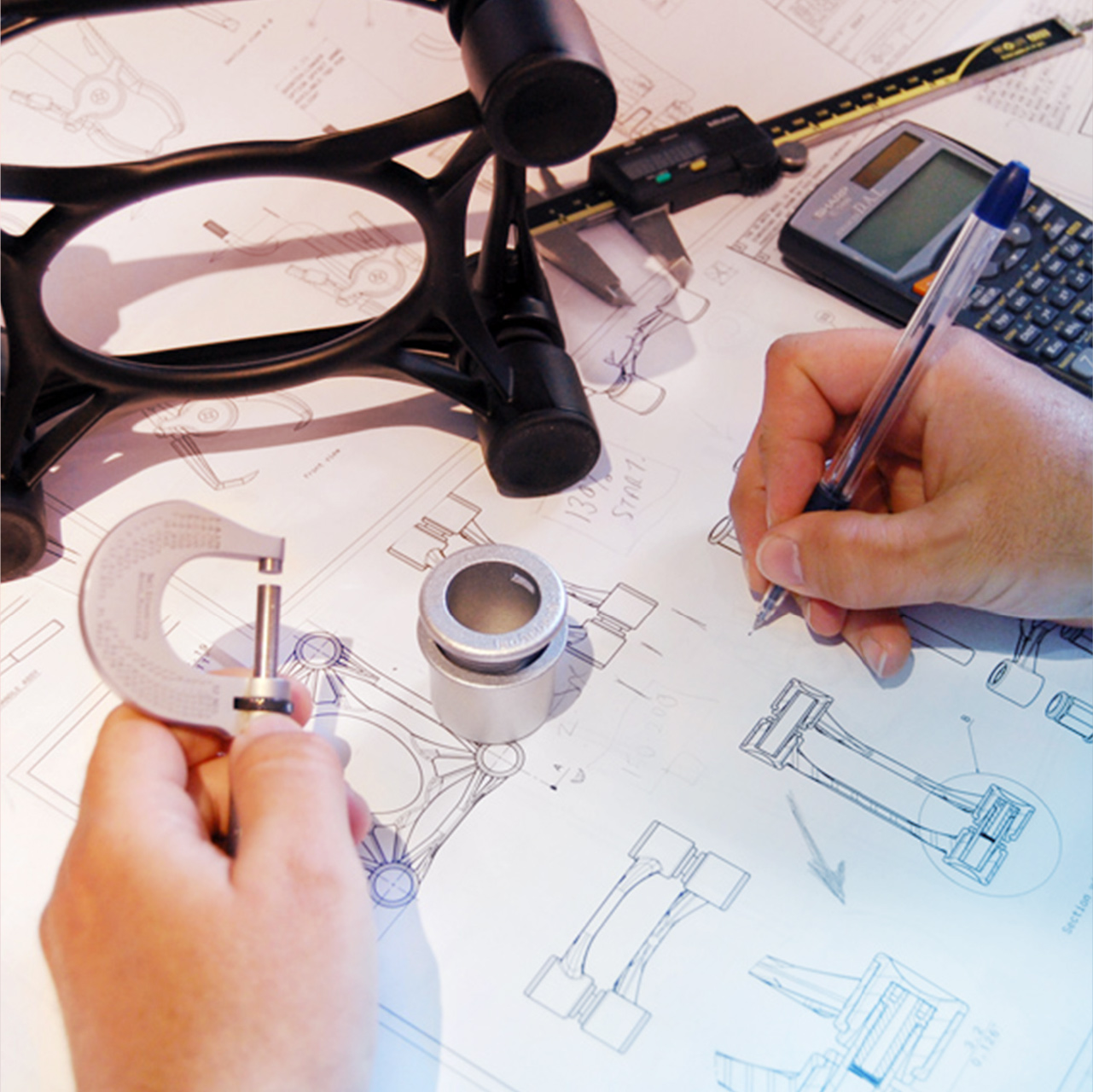

Manufacturing Process

There are numerous manufacturing processes, each suited to specific types of products, materials, and production requirements. Some of the most popular processes used for product manufacturing are: injection molding, extrusion, sheet metal forming, machining, CNC machining, welding, casting…

Manufacturing Process

There are numerous manufacturing processes, each suited to specific types of products, materials, and production requirements. Some of the most popular processes used for product manufacturing are: injection molding, extrusion, sheet metal forming, machining, CNC machining, welding, casting…

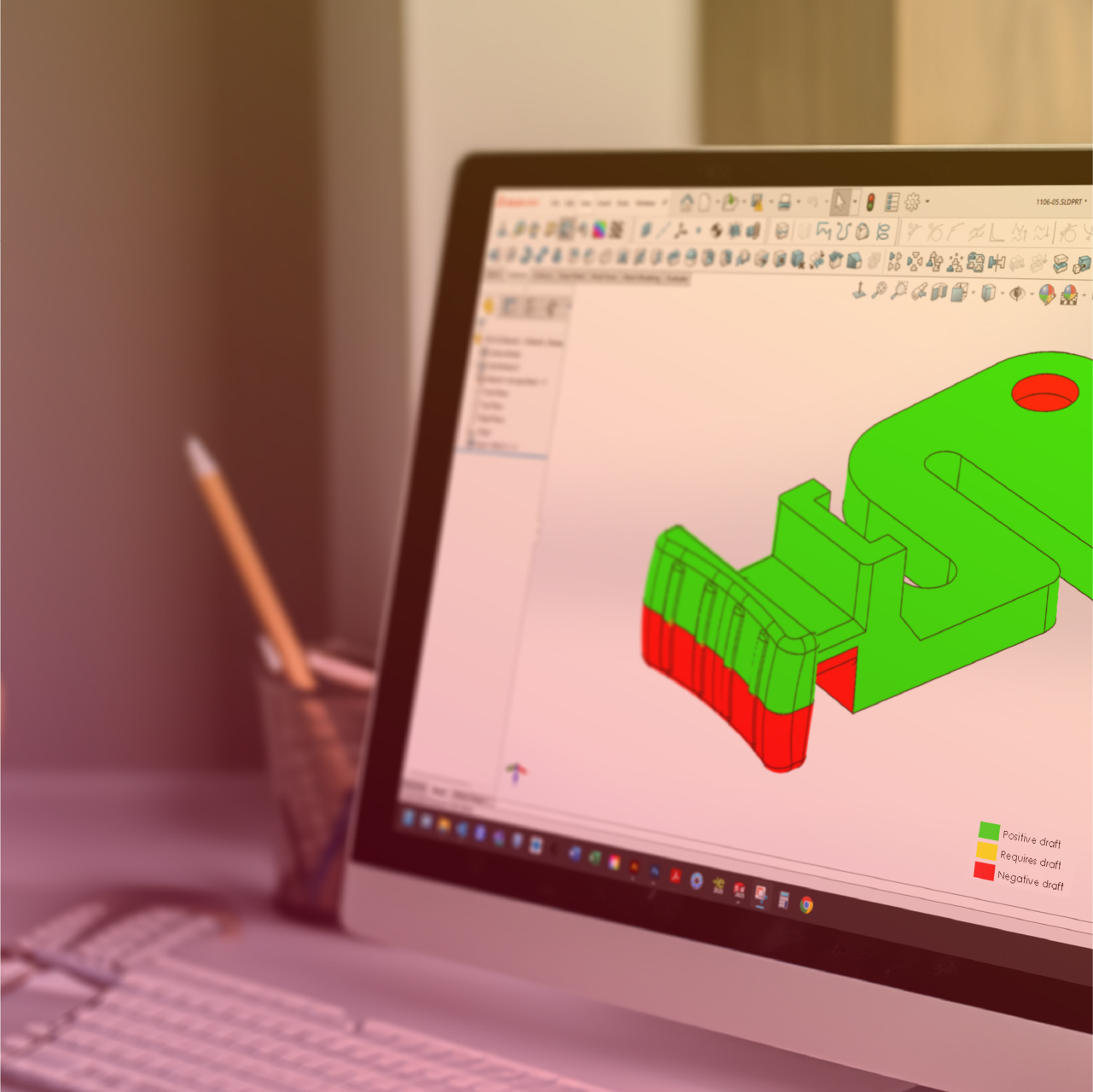

Designing for the Process

After a suitable manufacturing process has been established to make a part, our team designs all features of that part to suit the process. For example, injection molding requires a draft to be added to all part features so the given part can de-mold from the tool.

Designing for the Process

After a suitable manufacturing process has been established to make a part, our team designs all features of that part to suit the process. For example, injection molding requires a draft to be added to all part features so the given part can de-mold from the tool.

RFQ (Request for Quote)

A major part of any product development process is choosing the right manufacturer(s) for your product. The Spark team creates an RFQ package with technical drawings and 3D files for manufacturers to review and quote. The quotes are analyzed and our team consults our clients on the best fit for your project.

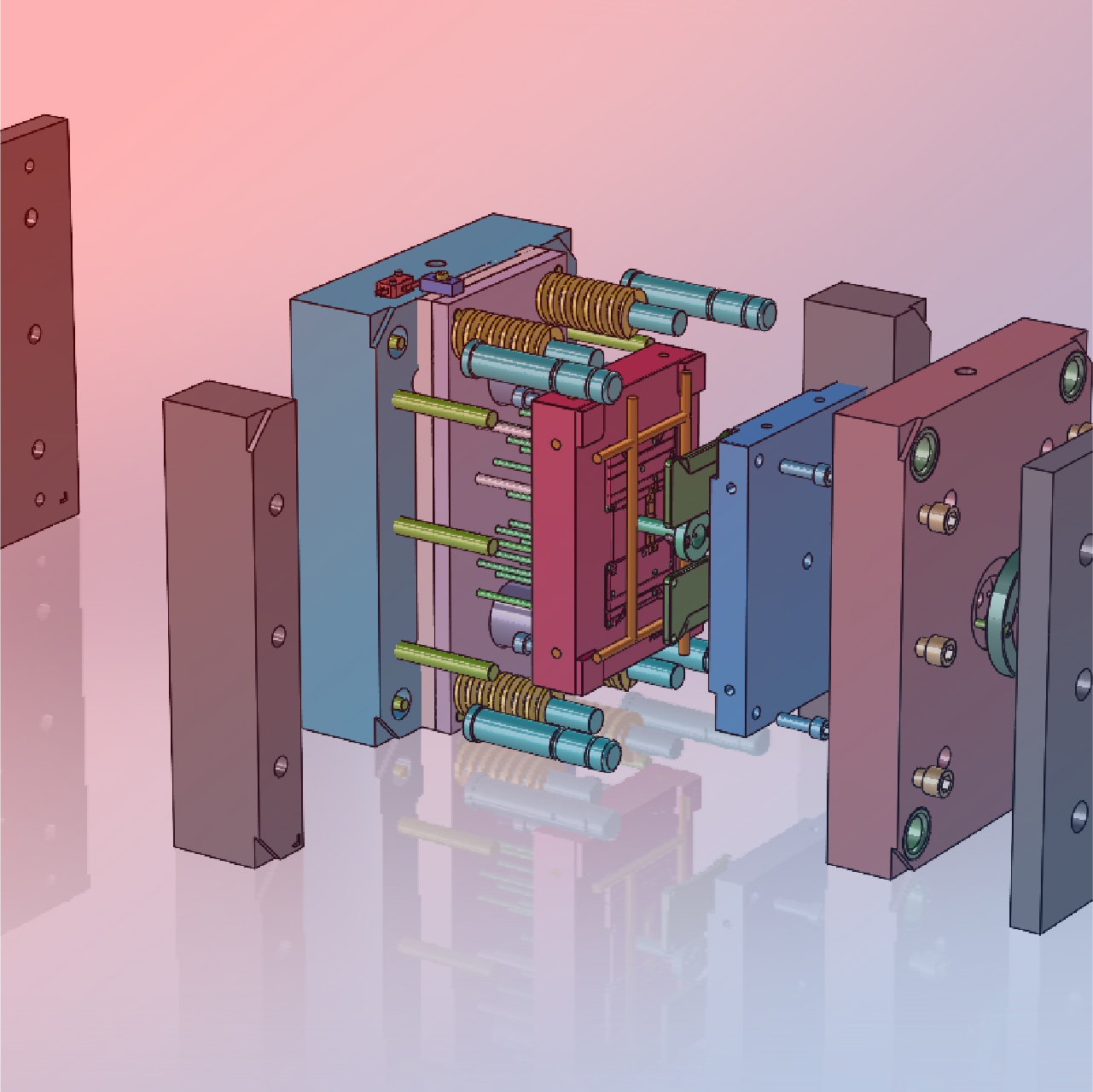

Tooling & Upfront Costs

Many manufacturing processes require a tool to be designed before a production part is made. Usually these tools have a large upfront cost that needs to be calculated into the overall costs of the project. Our team can guide you to choose the right manufacturer with the right set up for your project

Tooling & Upfront Costs

Many manufacturing processes require a tool to be designed before a production part is made. Usually these tools have a large upfront cost that needs to be calculated into the overall costs of the project. Our team can guide you to choose the right manufacturer with the right set up for your project

T1 Samples

T1 samples typically refer to the first set of samples produced during the initial trial run of a new product or manufacturing process. These samples are created to test and validate the manufacturing processes, product design, and quality standards before full-scale production begins.

The primary purpose of T1 samples is to identify and address any issues, defects, or inefficiencies in the manufacturing process. This includes evaluating the quality of the product and ensuring that it meets design specifications.

T1 Samples

T1 samples typically refer to the first set of samples produced during the initial trial run of a new product or manufacturing process. These samples are created to test and validate the manufacturing processes, product design, and quality standards before full-scale production begins.

The primary purpose of T1 samples is to identify and address any issues, defects, or inefficiencies in the manufacturing process. This includes evaluating the quality of the product and ensuring that it meets design specifications.

DFM Reports

It is common for T1 samples to reveal issues that need to be addressed, such as design flaws, material inconsistencies, or process inefficiencies. The Spark team can identify and address these issues through DFM reports, capturing the issue and suggesting solutions.

DFM Reports

It is common for T1 samples to reveal issues that need to be addressed, such as design flaws, material inconsistencies, or process inefficiencies. The Spark team can identify and address these issues through DFM reports, capturing the issue and suggesting solutions.