Does a Prototype Have to Be Perfect?

People ask this question all the time. There is a misunderstanding in the general public where people think a prototype is meant to represent the final product down to every small detail. But, how perfect should it really be depends on the intention of that prototype and where you are in the design process.

There are many cases in which your prototype is a more of a tool to help test, understand, define aesthetic and develop function.

In some cases people are looking for a final prototype that specifically looks like a final product. These cases happen when people have the intension of presenting it to investors. So, of course, they want it to have the exact feel, texture, color and functionality as a manufactured product. When these prototypes are made you can’t even notice that its hand painted or 3d printed in some cases. They look like the real deal.

What people don’t understand is that those final prototypes already went through all the validation necessary in order to reach that level of detail. It’s difficult to define how many prototypes you will need in order to reach the final goal. The reality is, that it is rare the first prototype becomes the last.

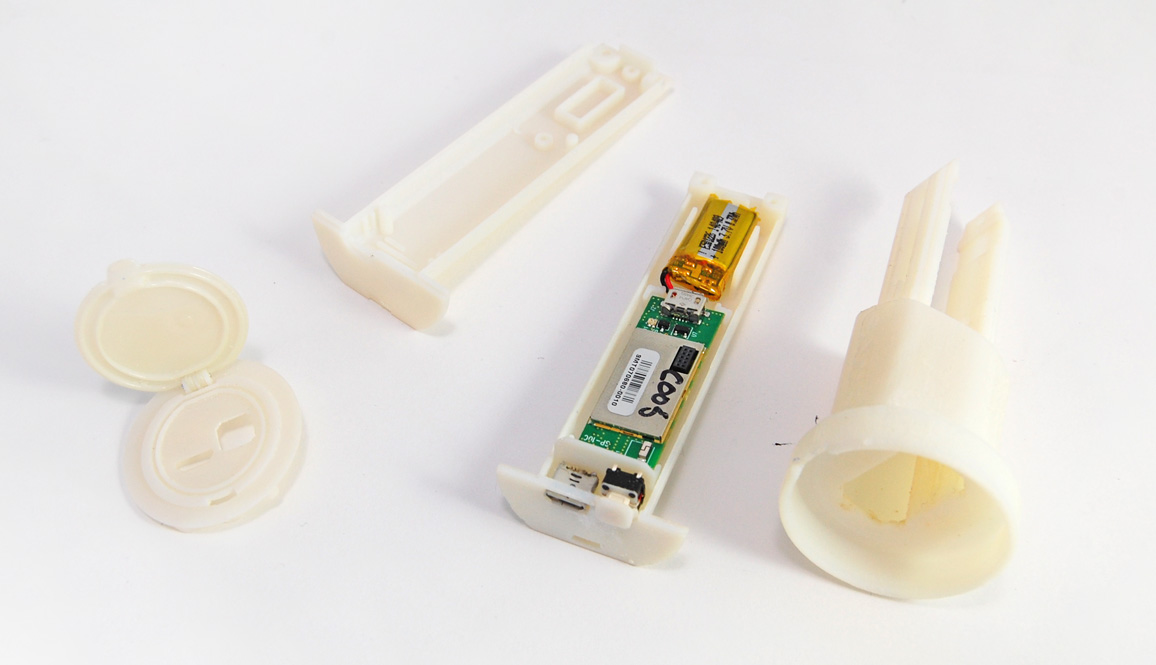

Here are some images that show how a prototype can evolve using in-house 3D Print of an end cap and a rubber 3d print with variations.

How are Prototypes Made?

The properties in which you build a prototype depends on the size and the material of the final product intention. There are handmade rudimentary prototypes that start off as paper or cardboard. And they even remain that way throughout an experimental phase. The initial form helps you get a sense of the overall shape. Once you have figured out the basics, it’s time to explore different and more professional techniques.

In some case they get stronger and evolve into gator board or even acrylics or styrene sheets. If needed they can be built from wood or 3D printed in plastic and in other cases metal sheet.

Once ambiguities are cleared, each prototype is perfected and created to resolve concerns by testing. I like to refer to prototypes as cooking experiments, they are a simmering process that takes time until it’s fully cooked. The final end goal or meal determines how long it’ll take to cook or validate your project.

That final prototype which is fully functional, and finished to replicate the exact version of the final product is not always needed. But if you do need it here are some examples of prototypes we have built:

Whichever stage of the prototyping process you are or the level of perfection that your prototype may need don’t hesitate to contact us. We are here to help!