Electronic Communication Device

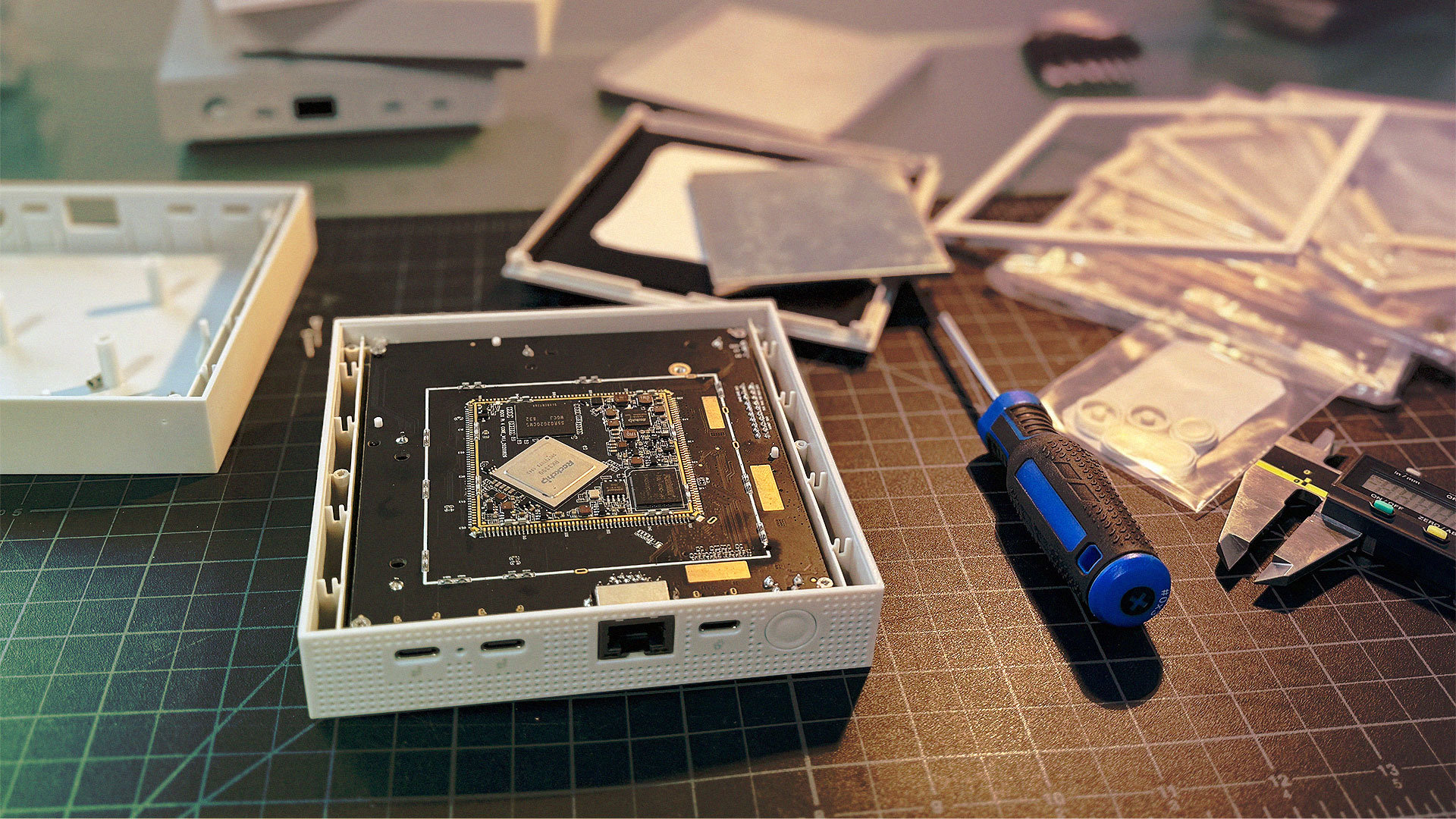

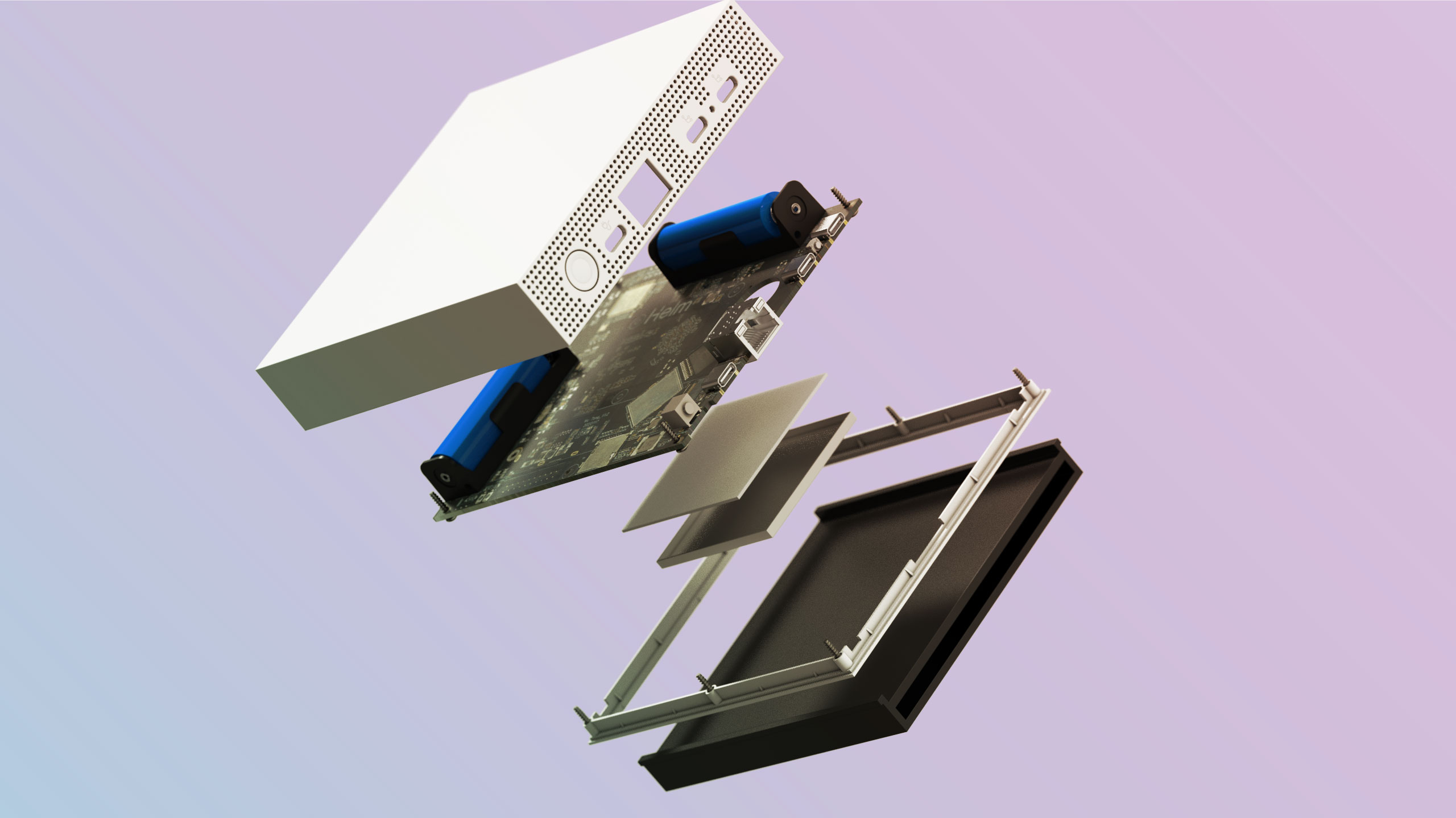

Spark worked on developing a housing for an electronic communication device. This project was developed to production intent with various levels of prototypes and collaboration with the client’s electronics developers.

Spark worked on developing a housing for an electronic communication device. This project was developed to production intent with various levels of prototypes and collaboration with the client’s electronics developers.

Manufacturing Process

The heat sink was designed with a unique strategy to utilize the extrusion manufacturing process because of its cost-effectiveness. The base, which acted as the heat sink, was extruded from aluminum, a highly efficient heat conductor, and then post-processed by cutting and machining. The aluminum heat sink effectively dissipated heat from critical areas.

Efficient Heat Dissipation

One of the major design criteria was to create an internal heat sink system that would dissipate the generated heat from internal electronics.

Efficient Heat Dissipation

One of the major design criteria was to create an internal heat sink system that would dissipate the generated heat from internal electronics.

Single piece main housing with front light indicator, rear power button and connectors

PCB with connectors and batteries

Heat sink connector

Bottom housing secures heat sync through crush ribs and mounts to the top housing

Extruded aluminum heat sink

Rear Ventilation

The communication device was designed with ventilation at the rear to promote airflow and maintain a minimalistic aesthetic when viewed from the front.