Garlic Press

The garlic press is a kitchen tool project that was developed for Kitchen Innovations Inc. a kitchen tool company. The project required concept designs that were presented using hand sketches. The validation of the functionality of the cutting and mincing blades could only be truly tested after production tooling was kicked off.

Garlic Press

The garlic press is a kitchen tool project that was developed for Kitchen Innovations Inc. a kitchen tool company. The project required concept designs that were presented using hand sketches. The validation of the functionality of the cutting and mincing blades could only be truly tested after production tooling was kicked off.

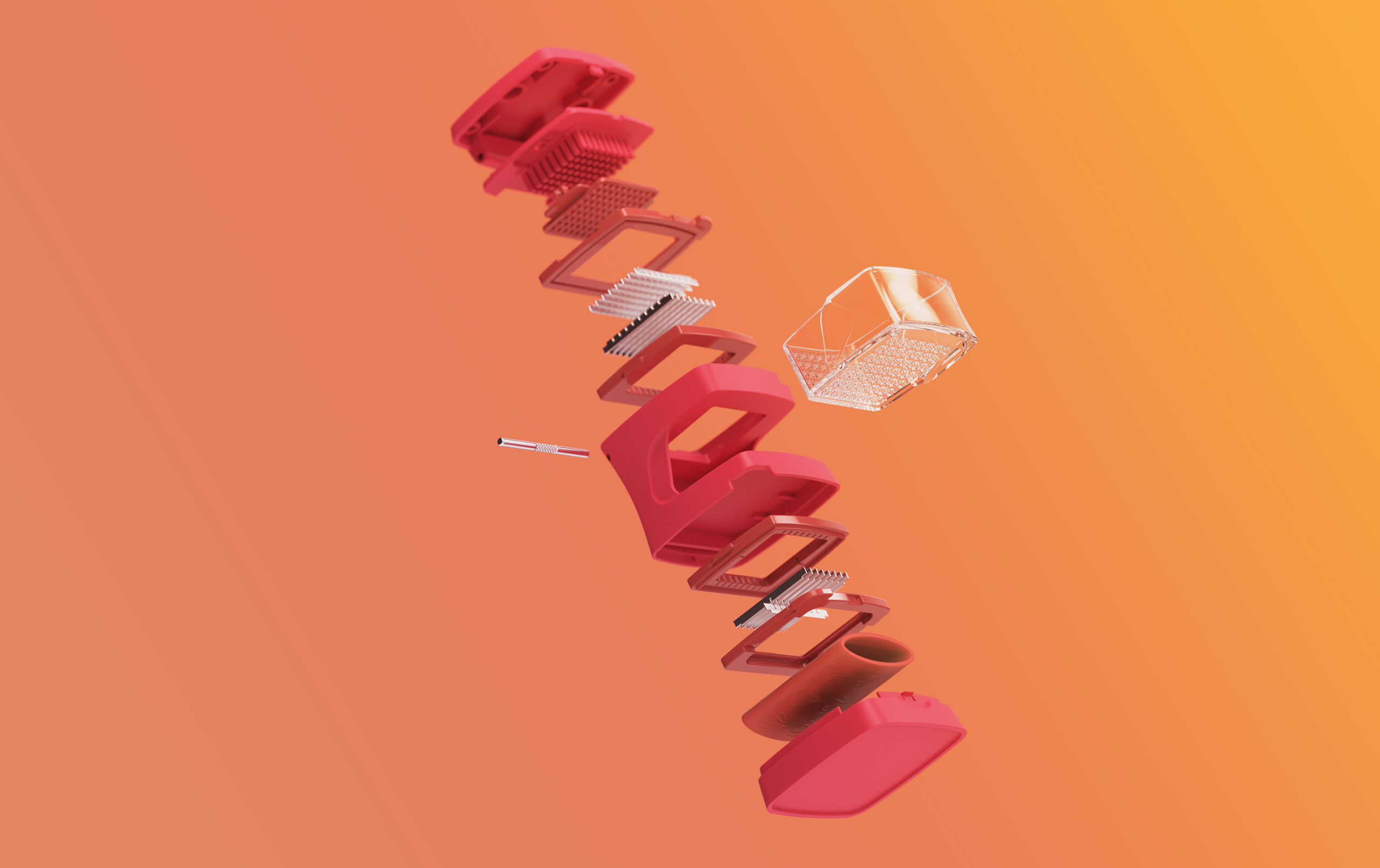

Top lid

Lid tines

Tine scraper

Dicer blade assembly

Storage container

Main body

Knurled hinge pin

Slicer blade assembly

Garlic peeler

Bottom cover / base

Features & Materials

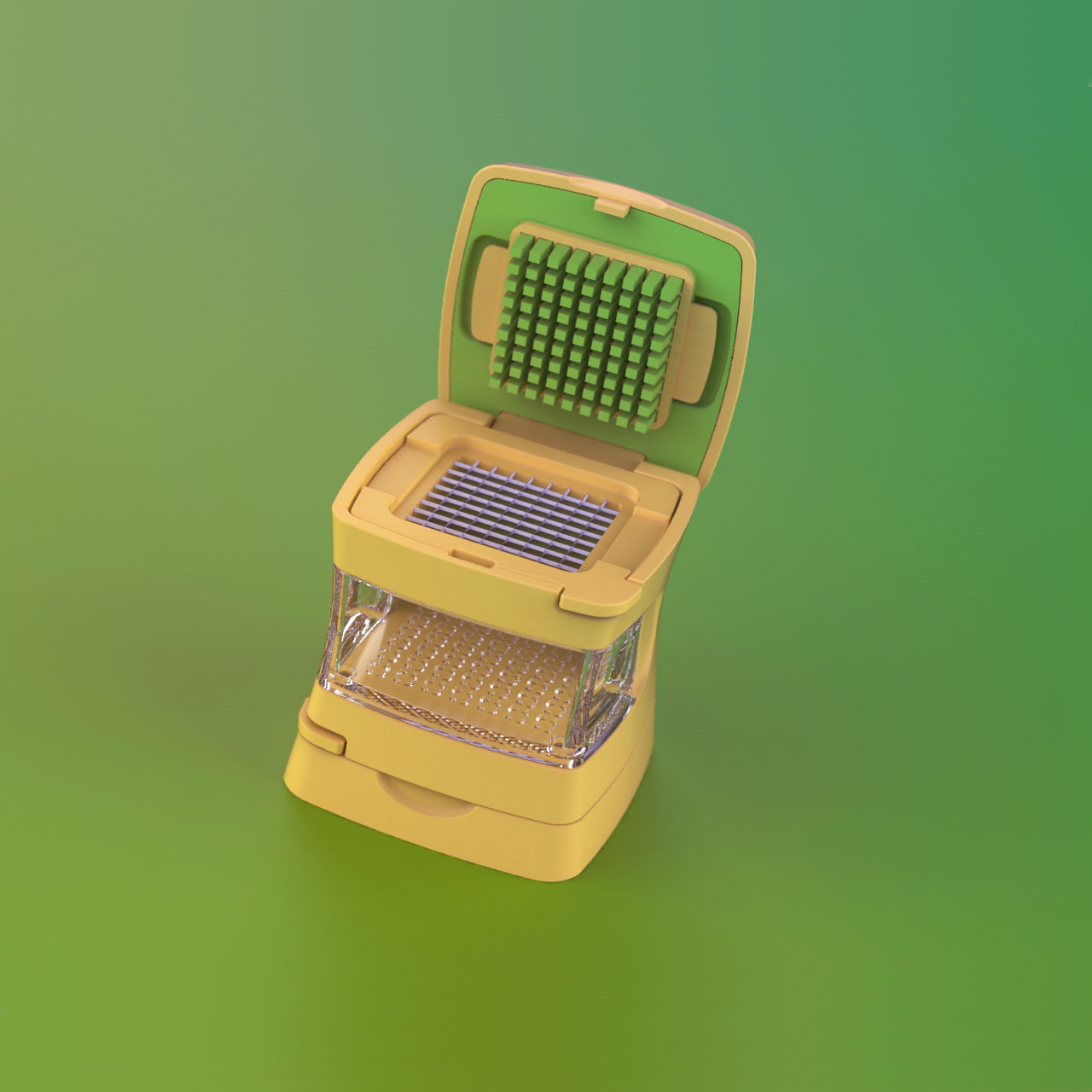

This garlic press features a thoughtfully designed ergonomic lid that fits perfectly in your palm. The well-balanced grip provides optimal control and minimizes hand fatigue, allowing you to crush garlic cloves with ease. Featuring food-grade stainless steel blades. Its robust construction ensures exceptional durability, and the corrosion-resistant material guarantees that the press remains in pristine condition even with frequent use and regular cleaning.

Features & Materials

This garlic press features a thoughtfully designed ergonomic lid that fits perfectly in your palm. The well-balanced grip provides optimal control and minimizes hand fatigue, allowing you to crush garlic cloves with ease. Featuring food-grade stainless steel blades. Its robust construction ensures exceptional durability, and the corrosion-resistant material guarantees that the press remains in pristine condition even with frequent use and regular cleaning.

Steel Safe Design Strategy

The force required to cut the garlic as well as the sharpness of the cutting blades made it difficult to test the design during the prototype process. As a result, the strategy of steel safe design was implemented on all the features that needed tuning. Features and parts were made intentionally too loose and carefully the steel on the tools was gradually shaved off to tighten the parts to the desired specification.

Steel Safe Design Startegy

The force required to cut the garlic as well as the sharpness of the cutting blades made it difficult to test the design during the prototype process. As a result, the strategy of steel safe design was implemented on all the features that needed tuning. Features and parts were made intentionally too loose and carefully the steel on the tools was gradually shaved off to tighten the parts to the desired specification.