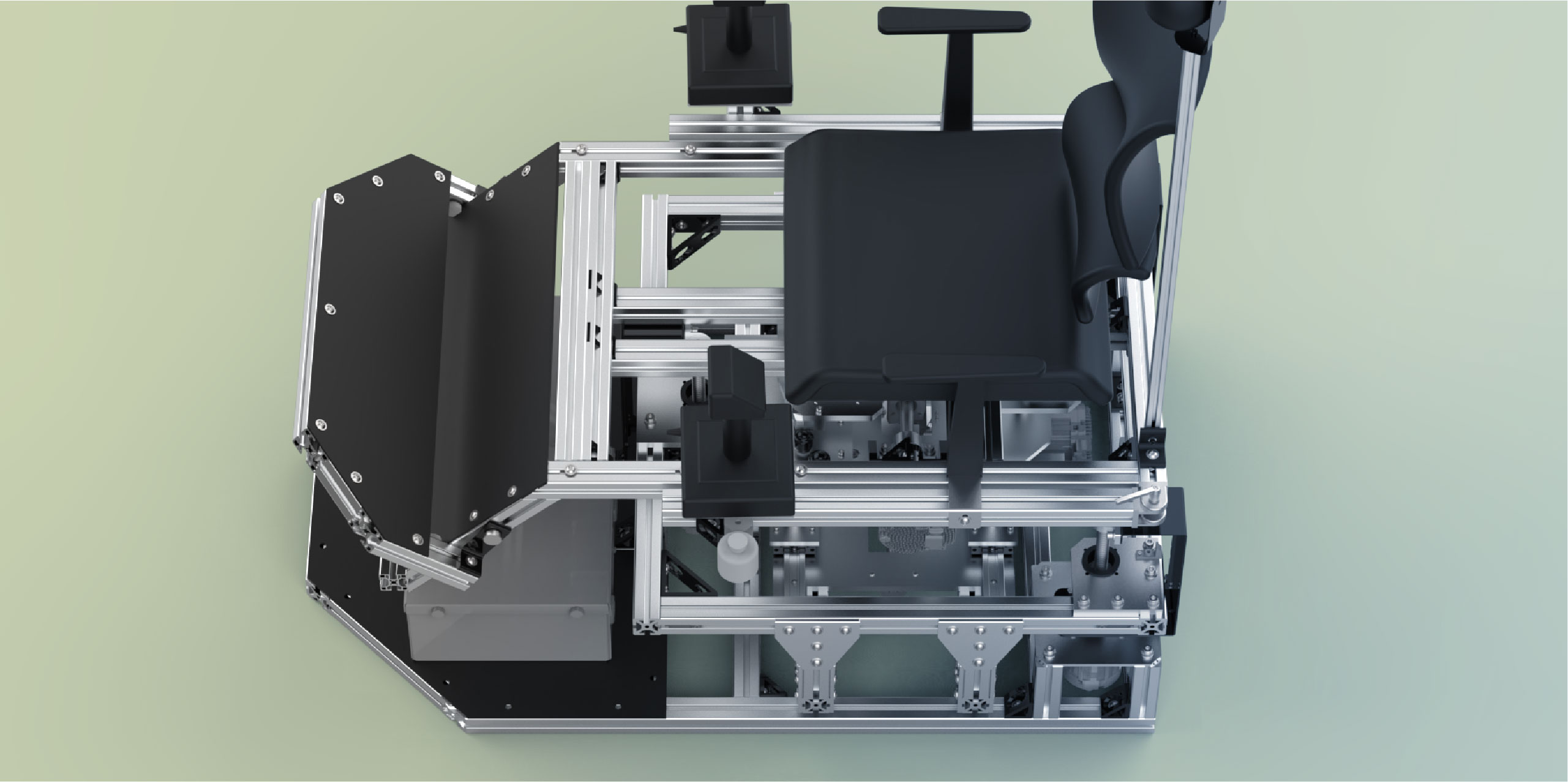

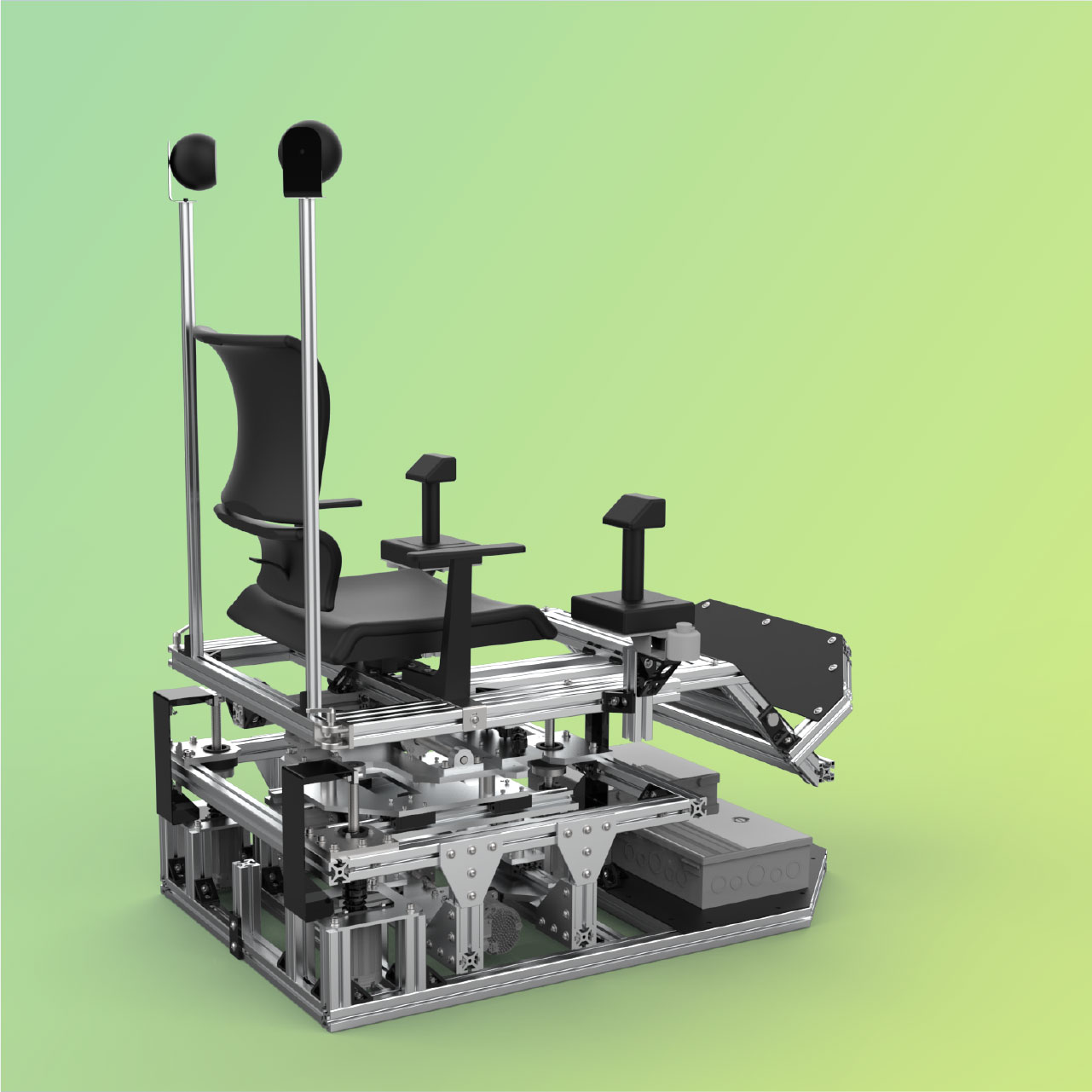

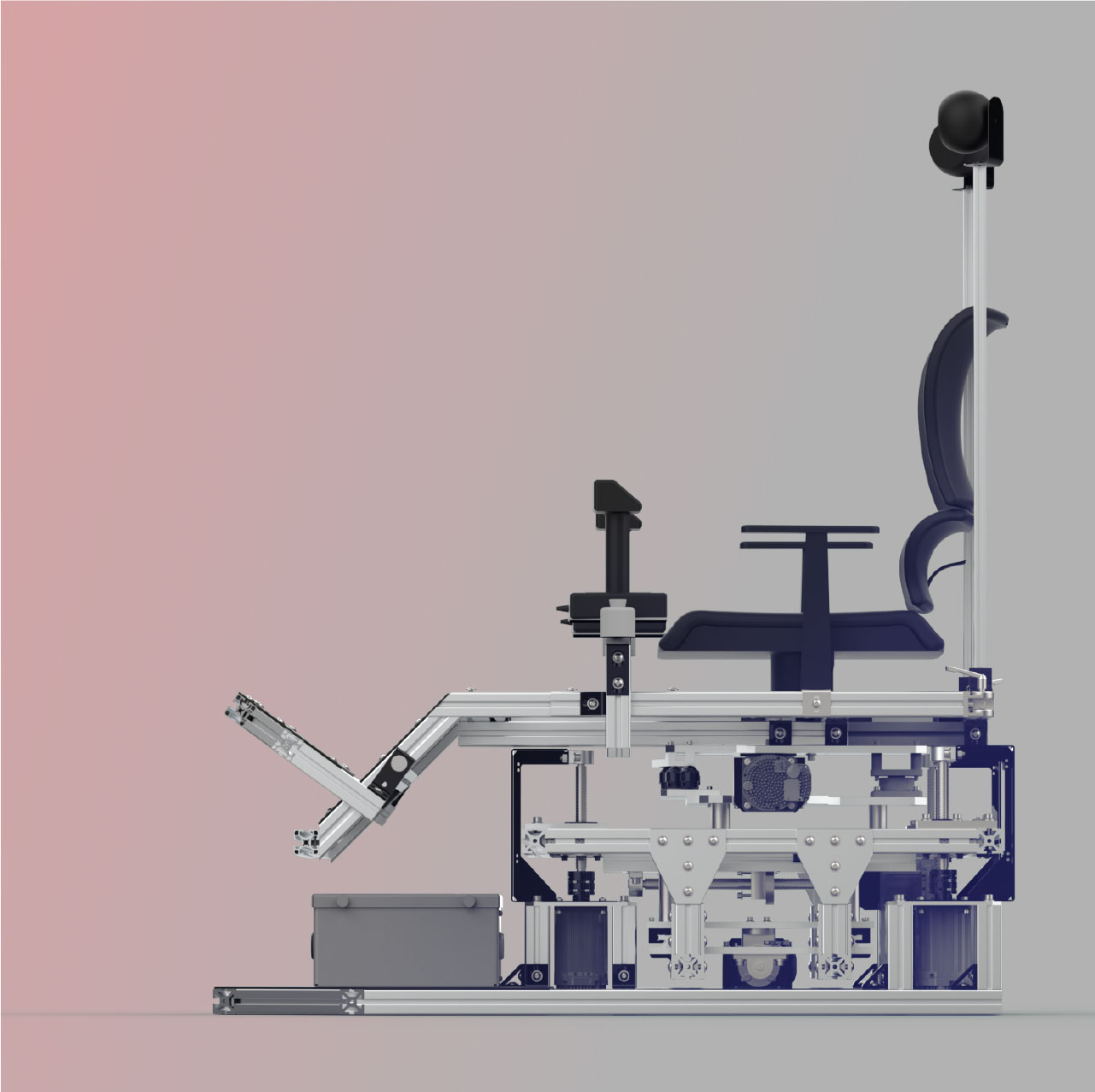

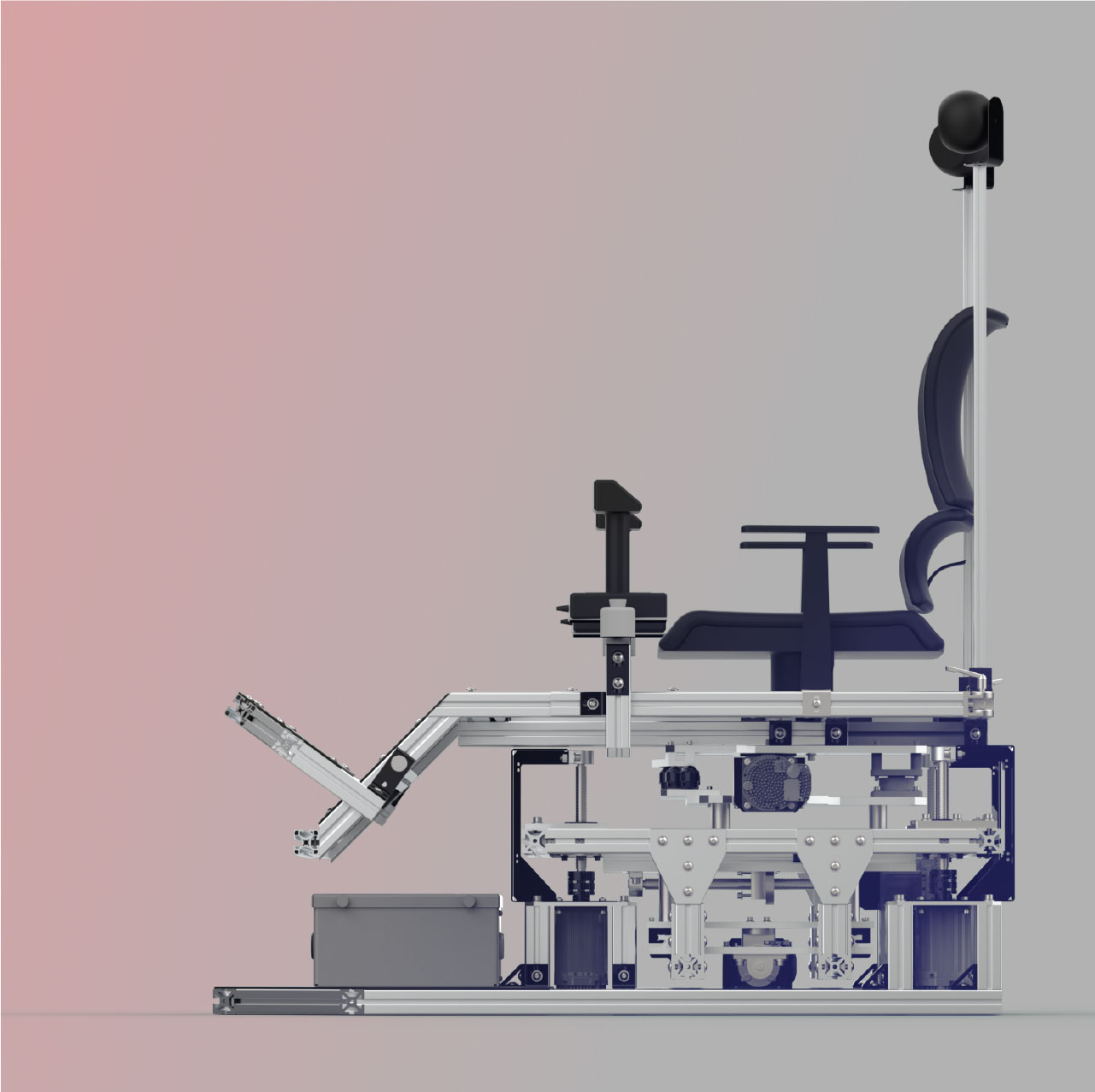

Motion Seat

Spark Innovation’s mechanical design team were put to the ultimate challenge in the design of a UAV flight motion simulator seat. Developed for a local tech corporation to deploy at a show under very tight deadlines and budget.

Budget and Cost Savings

The budget for this project was a very large part of the design startegy. Spark engineers used 80/20 aluminium extrusions for the frame and chassis. This allowed for quick testing and cost-effective manufacturing. Saving the client costs of lengthy parts development.

Budget and Cost Savings

The budget for this project was a very large part of the design strategy. Spark engineers used 80/20 aluminium extrusions for the frame and chassis. This allowed for quick testing and cost-effective manufacturing. Saving the client costs of lengthy parts development.

XYZ Motion

The seat required mechanical motion through actuators and motors in all three XYZ directions. The mounting and location of all components was tested and adjusted with the help of the 80/20 system of aluminium extrusions and brackets.

XYZ Motion

The seat required mechanical motion through actuators and motors in all three XYZ directions. The mounting and location of all components was tested and adjusted with the help of the 80/20 system of aluminium extrusions and brackets.