Elevated Feeder for Pets

This project aimes to redefine pet feeding systems, containing spills, minimizing floor and wall damage, preventing water from saturating spilled food, and enabling easy cleaning. These systems save pet owners time and money on cleaning and maintenance.

This project aimes to redefine pet feeding systems, containing spills, minimizing floor and wall damage, preventing water from saturating spilled food, and enabling easy cleaning. These systems save pet owners time and money on cleaning and maintenance.

The challenge

The challenge was to design a feeding system that elevated bowls to a height suitable for pets, addressing issues like gastric distress, bloating, and chronic fatigue. The system needed to separate spilled water from food, making it easier to clean and recycle. This design also aimed to improve the feeding experience by allowing the station to be placed in a more convenient area of the home.

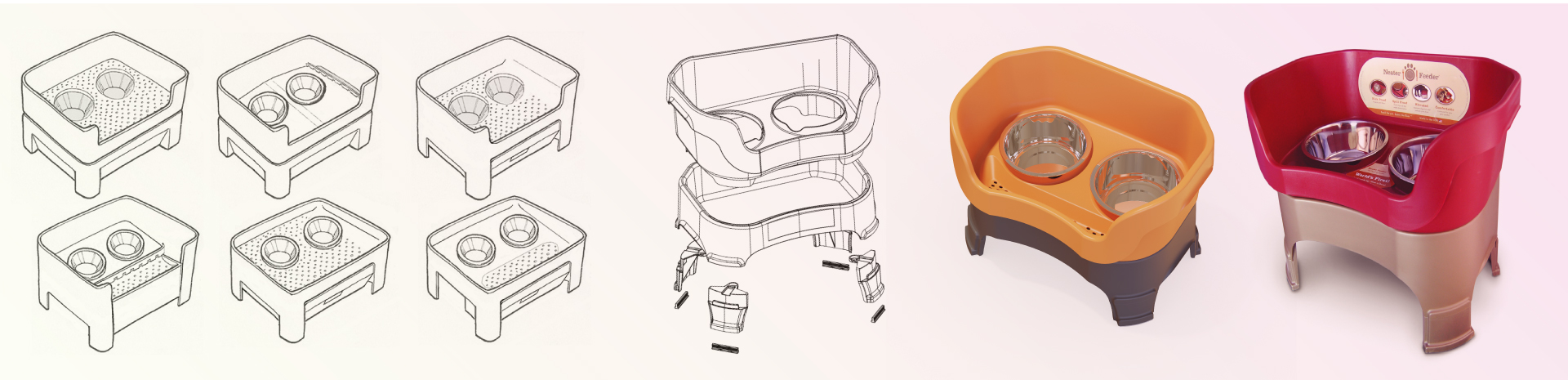

Concept Development

Once an idea transitions into a concept phase, sketches are used to define the shape, form, style, and function of the product. Several concepts were created and refined to present the client with multiple valid directions. Through evaluation and a refinement process, the concepts are funneled down to a single direction in preparation for prototyping, engineering development, documentation, and mass production.

Once an idea transitions into a concept phase, sketches are used to define the shape form style and function of the product. Several concepts were created and refined to present the client with multiple valid directions. Through evaluation and a refinement process, the concepts are funneled down to a single direction in preparation for prototyping, engineering development, documentation, and mass production.

Testing and Prototyping

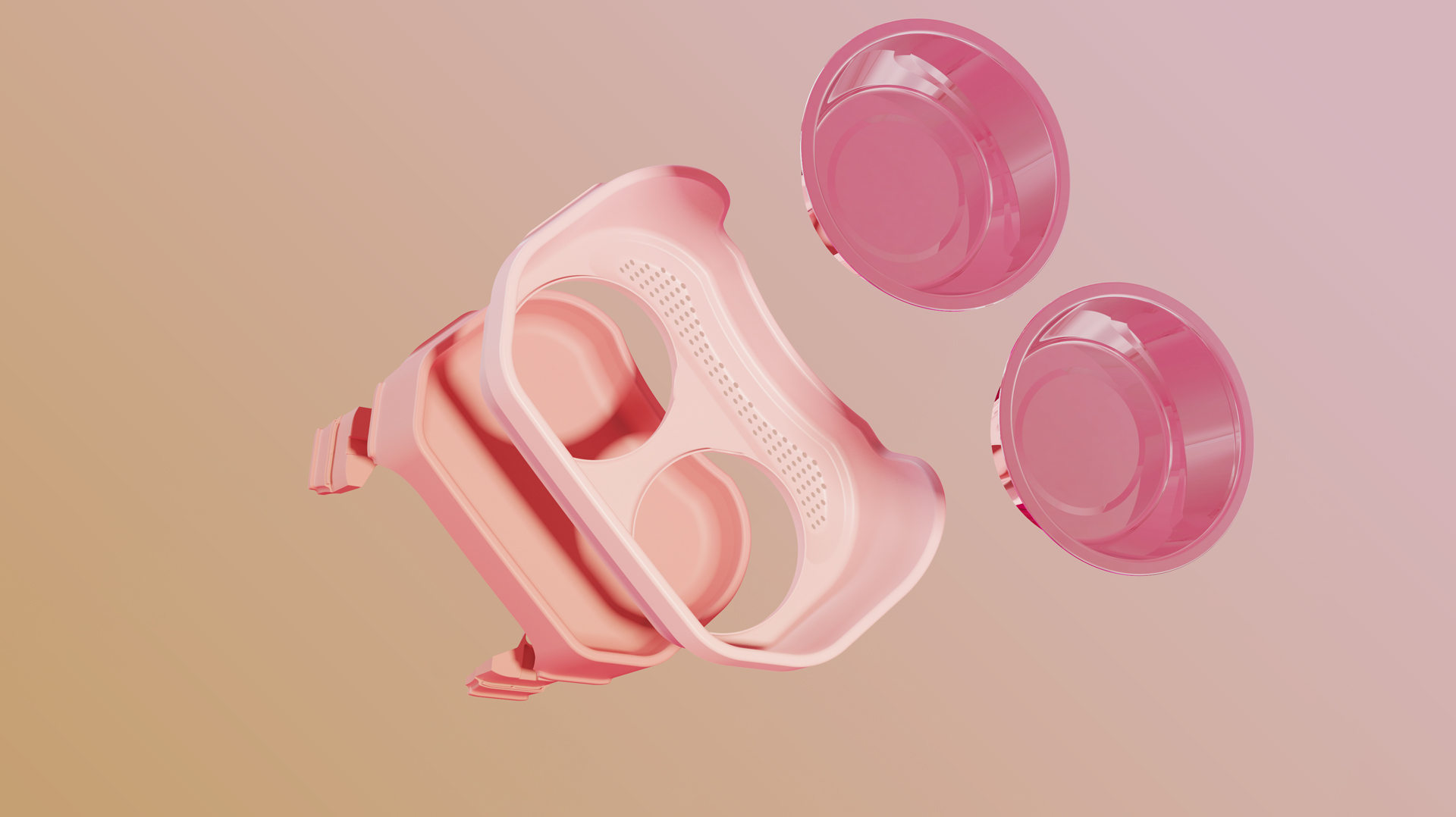

Spark’s testing and prototyping process centers around user research and rapid-prototyping. Our team utilizes 3D CAD to create models in the early stages of a project. For this project, fused deposition modeling (FDM) was used to prototype and validate the chosen concept. Testing at a one to one scale is essential to validate shape, form, style, and function. Through this process, measurements, key features, and challenges are defined and a new round of prototyping validates and moves the project one step closer to manufacturing.

Spark’s testing and prototyping process centers around user research and rapid-prototyping. Our team utilizes 3D CAD to create models in the early stages of a project. For this project, fused deposition modeling (FDM) was used to prototype and validate the chosen concept. Testing at a one to one scale is essential to validate shape, form, style, and function. Through this process, measurements, key features, and challenges are defined and a new round of prototyping validates and moves the project one step closer to manufacturing.

Ergonomic Product Design

Ergonomic design focuses on developing objects and spaces that are suitable for the user’s needs. In the case of pet feeders, this involves considering the size, height, and weight of dogs and cats. The primary goals of ergonomic design in this context include ensuring comfort, minimizing the number of steps required for various tasks, creating intuitive interactions, and enhancing the overall user experience for both pets and their owners.

Ergonomic Product Design

Ergonomic design focuses on developing objects and spaces that are suitable for the user’s needs. In the case of pet feeders, this involves considering the size, height, and weight of dogs and cats. The primary goals of ergonomic design in this context include ensuring comfort, minimizing the number of steps required for various tasks, creating intuitive interactions, and enhancing the overall user experience for both pets and their owners.

Industrial Design

Industrial design is about creating and optimizing products for both users and manufacturers, it bridges user needs with creative design and collaboration. At Spark, industrial designers translate consumer needs into viable product designs. Industrial design intent refers to the documentation provided to mechanical designers after concept approval, including CAD geometry, drawings, renderings, models, and prototypes.

Food & Water bowls

Spilled water drain holes

Upper reservoir

Lower Reservoir

Leg extensions