Mechanical Engineering

Mechanical engineering specifically focuses on the design, development, and optimization of mechanical components and systems within a product. These services are essential in ensuring that a product is mechanically sound, functions as intended, and meets all safety and performance requirements.

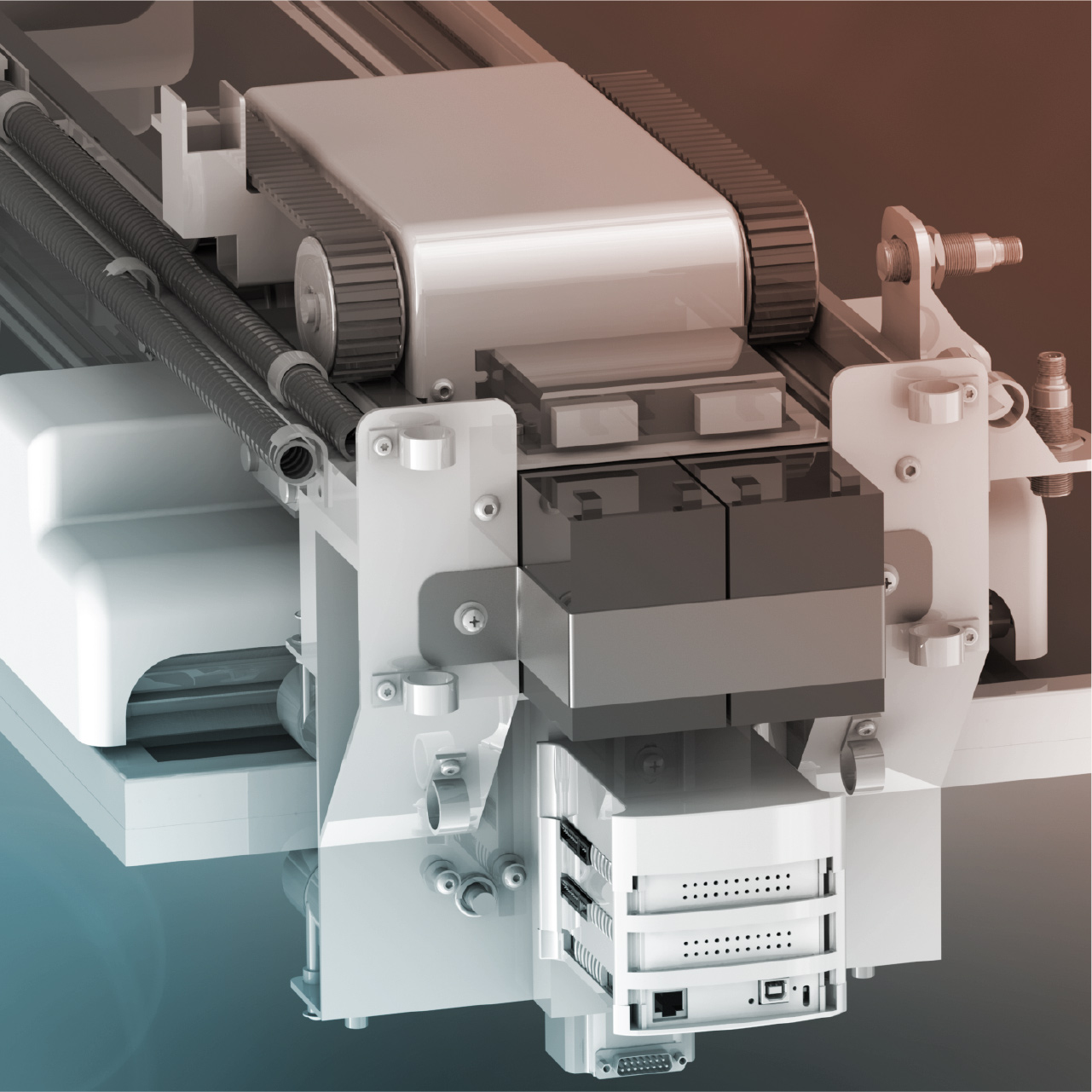

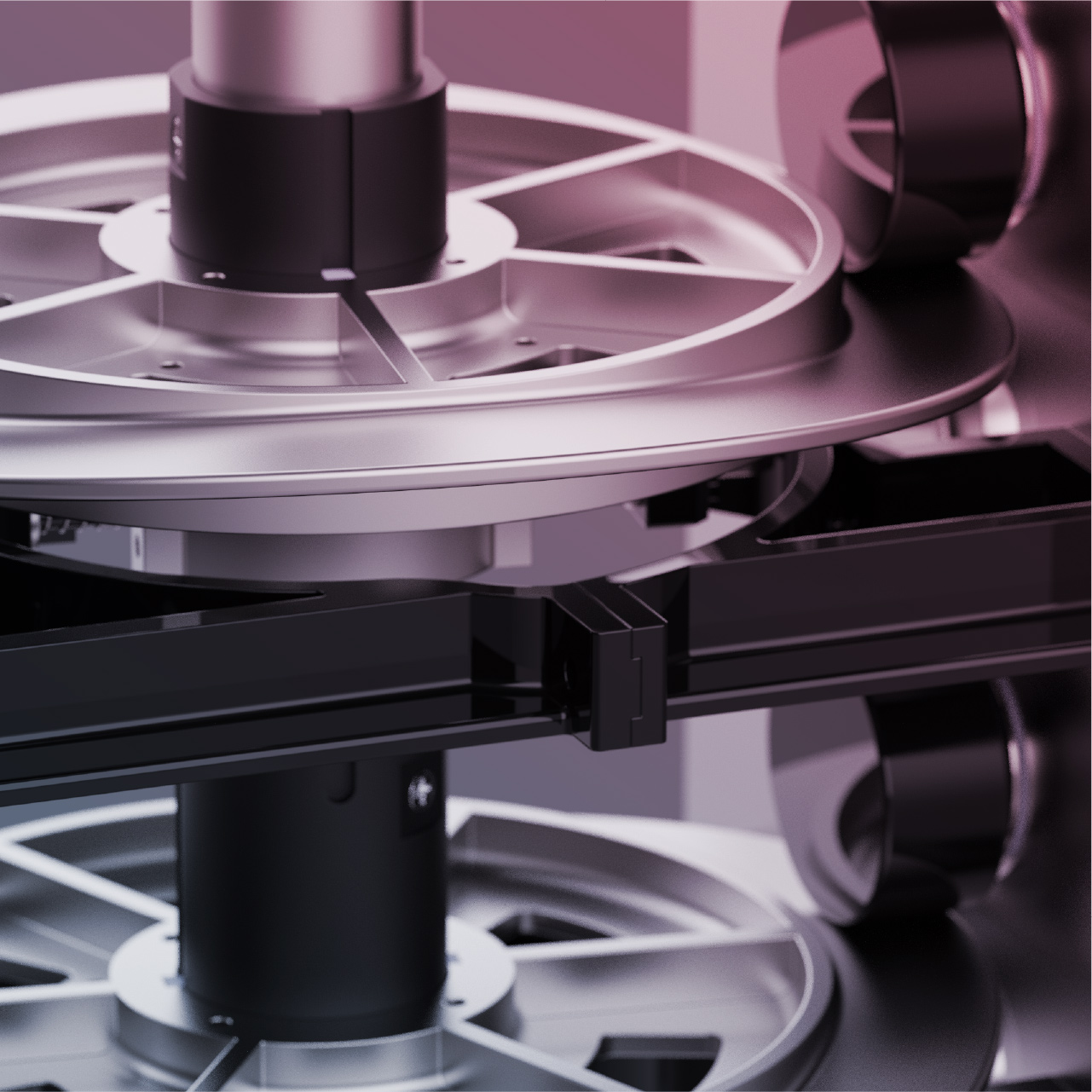

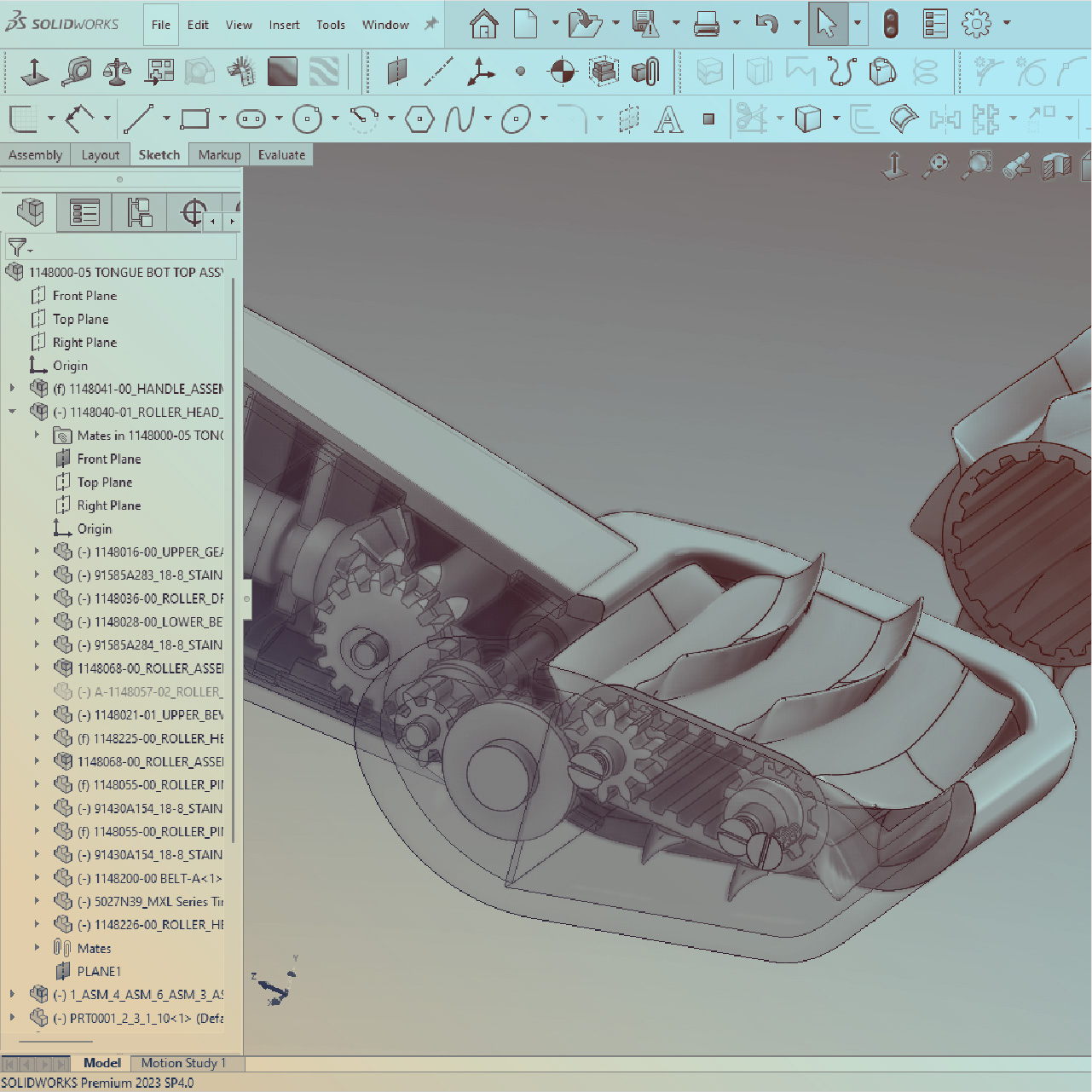

3D Modeling

3D modeling in the context of product development consists of creating three-dimensional digital models of parts and assemblies for various purposes and strategies. We are experts at designing in 3D for various stages of the product development process. These 3D models play an essential role in the engineering of parts and products. The Spark team are experts in Catia and Solidworks 3D and 2D modeling, along with Illustrator, Photoshop, and Keyshot

3D Modeling

3D modeling in the context of product development consists of creating three-dimensional digital models of parts and assemblies for various purposes and strategies. We are experts at designing in 3D for various stages of the product development process. These 3D models play an essential role in the engineering of parts and products. The Spark team are experts in Catia and Solidworks 3D and 2D modeling, along with Illustrator, Photoshop, and Keyshot

Product Assembly

Product design can require the development of how a product is assembled. This assembly strategy can be for simply for prototype, production, assembly line assembly, consumer assembly, and post use disassembly. There are many design strategies to help create an accurate assembly process.

Product Assembly

Product design can require the development of how a product is assembles. This assembly strategy can be for simply for prototype, production, assembly line assembly, consumer assembly, and post use disassembly. There are many design strategies to help create an accurate assembly process.

Mechanical Testing & Validation

During the product design life-cycle, testing and validating prototypes and production samples are essential in the product development process, to prove and test ideas. Ensuring that prototypes and/or production samples function as intended, meet safety and quality standards, and are ready for further development is an important repeatable exercise performed by our engineering team throughout the design of any product.

Mechanical Testing & Validation

During the product design life-cycle, testing and validating prototypes and production samples are essential in the product development process, to prove and test ideas. Ensuring that prototypes and/or production samples functions as intended, meet safety and quality standards, and are ready for further development is an important repeatable exercise performed by our engineering team throughout the design of any product.

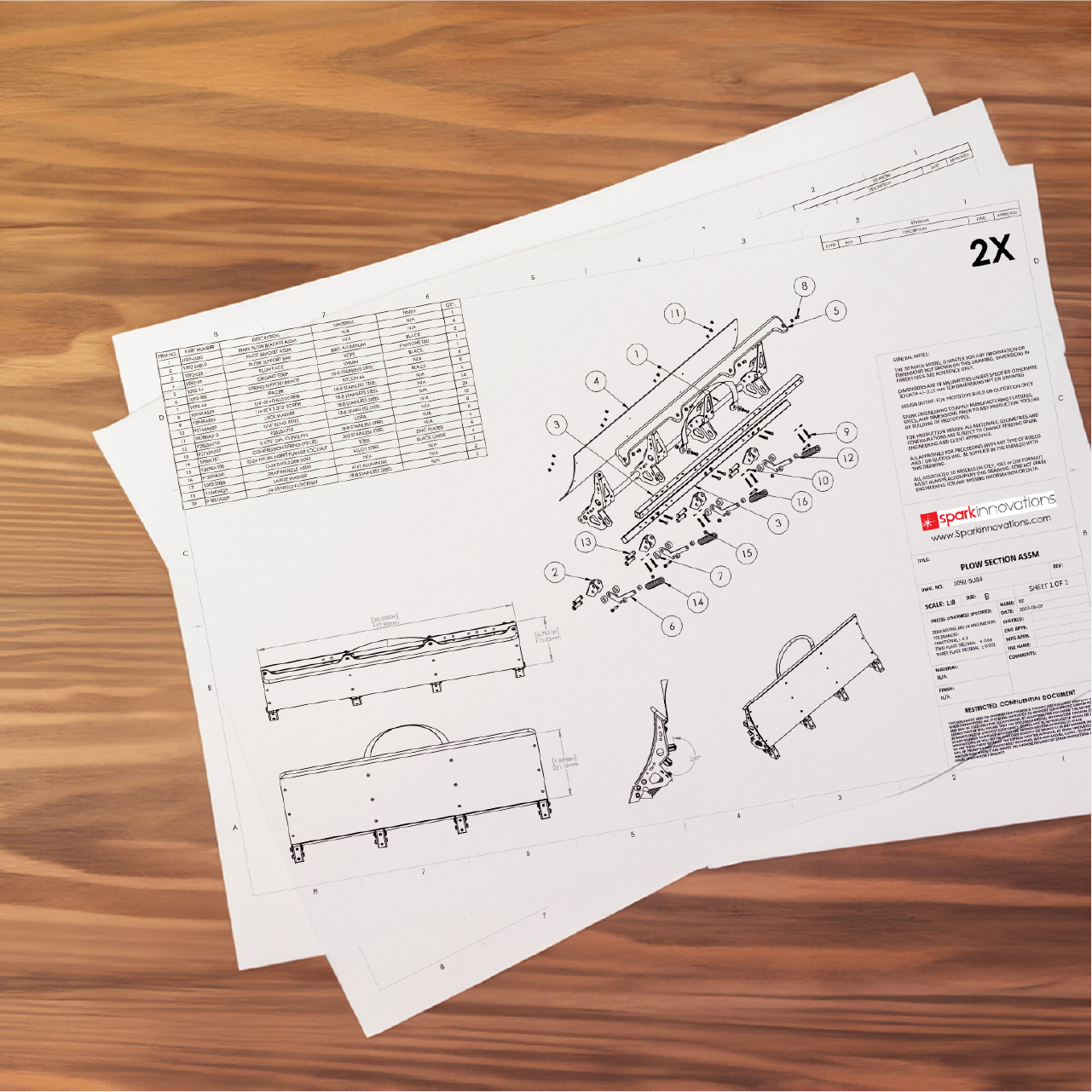

Technical Drawings

Technical drawings involve creating detailed and accurate drawings, diagrams, and illustrations of parts, processes and assemblies that convey technical information about a product, structure, or system. These drawings are used for conveying information to prototype technicians, production facilities and clients. They are often used for quoting a project at various stages of its development. Technical drawings can contain important notes on a production detail or strategy, they contain integral information about a parts dimensions, properties, finishes, production methods, colours.

Technical drawings serve as a visual means of communication, providing precise information for design, production, and documentation purposes.

Technical Drawings

Technical drawings involve creating detailed and accurate drawings, diagrams, and illustrations of parts, processes and assemblies that convey technical information about a product, structure, or system. These drawings are used for conveying information to prototype technicians, production facilities and clients. They are often used for quoting a project at various stages of its development. Technical drawings can contain important notes on a production detail or strategy, they contain integral information about a parts dimensions, properties, finishes, production methods, colours.

Technical drawings serve as a visual means of communication, providing precise information for design, production, and documentation purposes.

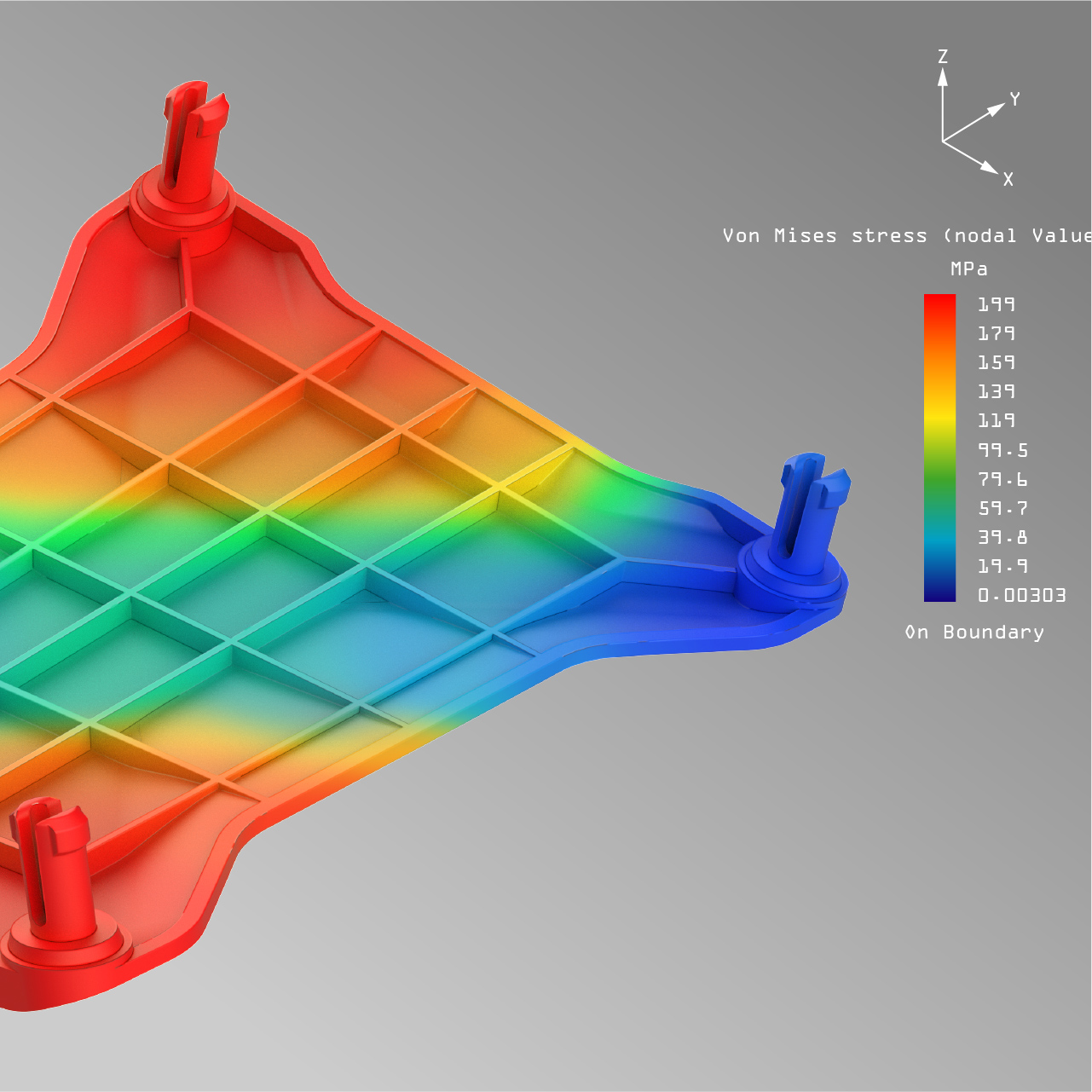

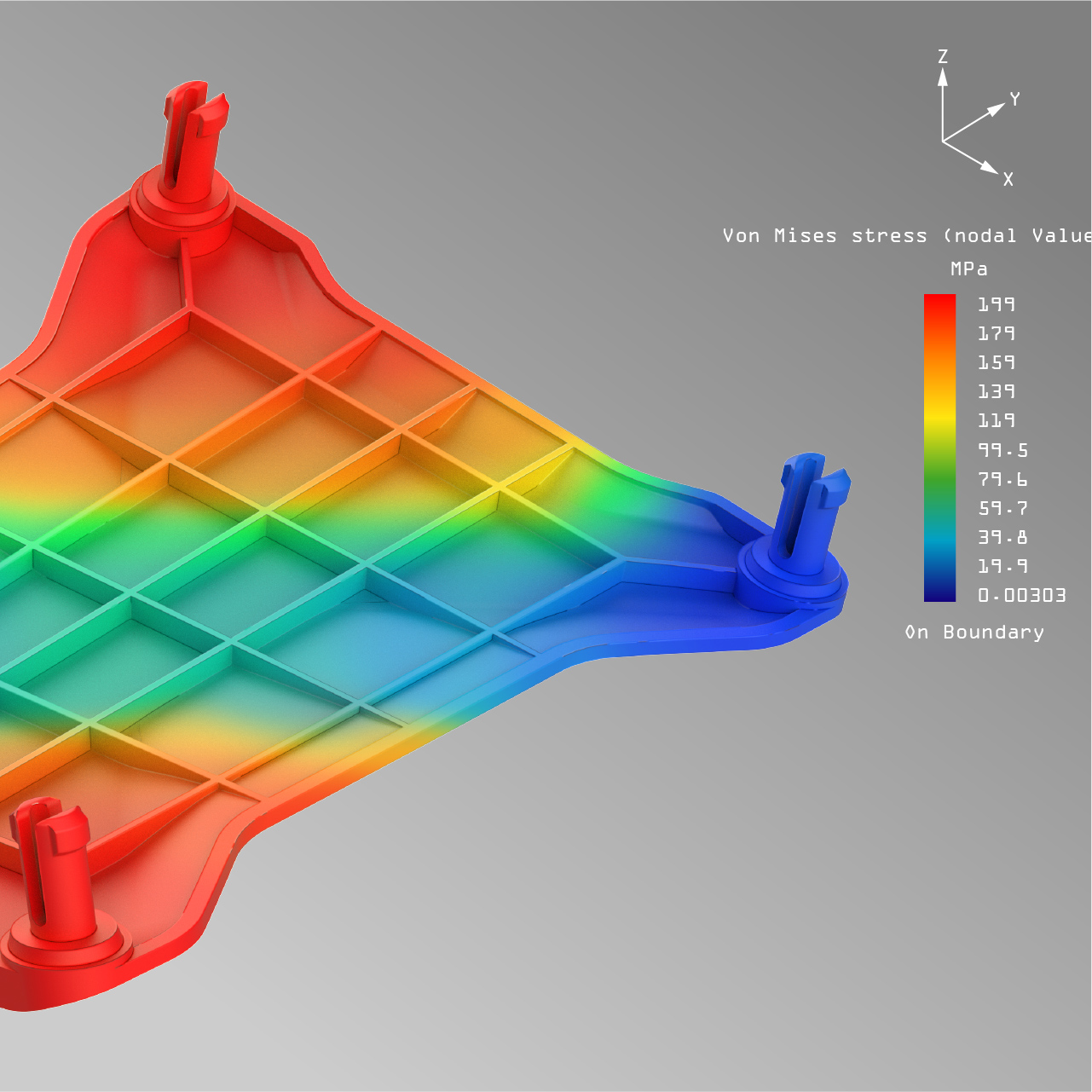

FEA (Finite Element Analysis)

FEA analysis is an area of mechanical engineering, it involves the use of FEA software and simulation techniques to analyze and optimize the behavior of mechanical structures and components. FEA analysis can help determine the structural integrity, strength, response to dynamic loads, buckling behavior, failure points, and other conditions. (Note: Some FEA testing may be outside of our team’s capabilities, please contact us to find out more).

FEA (Finite Element Analysis)

FEA analysis is an area of mechanical engineering, it involves the use of FEA software and simulation techniques to analyze and optimize the behavior of mechanical structures and components. FEA analysis can help determine part structural integrity, strength, response to dynamic loads, buckling behavior, failure points, and other conditions. (Note: Some FEA testing may be outside of our teams capabilities, please contact us to find out more).

Team Strategy

Our mechanical designers work in the same space as our industrial designers, product designers, and graphic designers to design your products seamlessly, efficiently and quickly. Our mechanical designers are experts in product cost-reduction and in designing to regulatory standards such as CSA, UL, ISO, FDA, ADA, FCC, JIS, VDE, etc.

Team Strategy

Our mechanical designers work in the same space as our industrial designers, product designers, and graphic designers to design your products seamlessly, efficiently and quickly. Our mechanical designers are experts in product cost-reduction and in designing to regulatory standards such as CSA, UL, ISO, FDA, ADA, FCC, JIS, VDE, etc.