Things you wish you knew before venturing into product development

When you are ready to venture into the product development process there are always expectations on how things should work out. They almost never do run as you expect. This document hopefully clarifies a few steps and what to expect when designing a new idea from concept to manufacturing.

Initial steps in defining the form of your idea

One of the first things you will discuss with your design firm is your concept. At Spark Innovations, we will build upon your idea and evolve that idea you have in your mind into viable product concepts.

Sketches will be created quickly as a process of rapid visualization that allows them to express and document successive ideas almost as quickly as they are thought of.

You should be provided with a few concepts in either sketches or renderings. We need detailed information from you to ensure the sketches are as accurate and complete as possible. If you are vague when explaining your design idea, it can be interpreted in different ways and will affect the accuracy of the sketches. If you have a clear image of that idea then try to be as precise as possible. Don’t be disappointed if the concepts don’t look quite as you imagined it to be. Each designer can have a different interpretation of what you want. You can always look into it together and refocus your thoughts. Always understand that a designer’s goal is to provide solutions that meet the needs of the end-user, you, and the manufacturer. So it is imperative that you discuss the results of the initial concepts before moving forward to the next step.

First steps into manufacturing

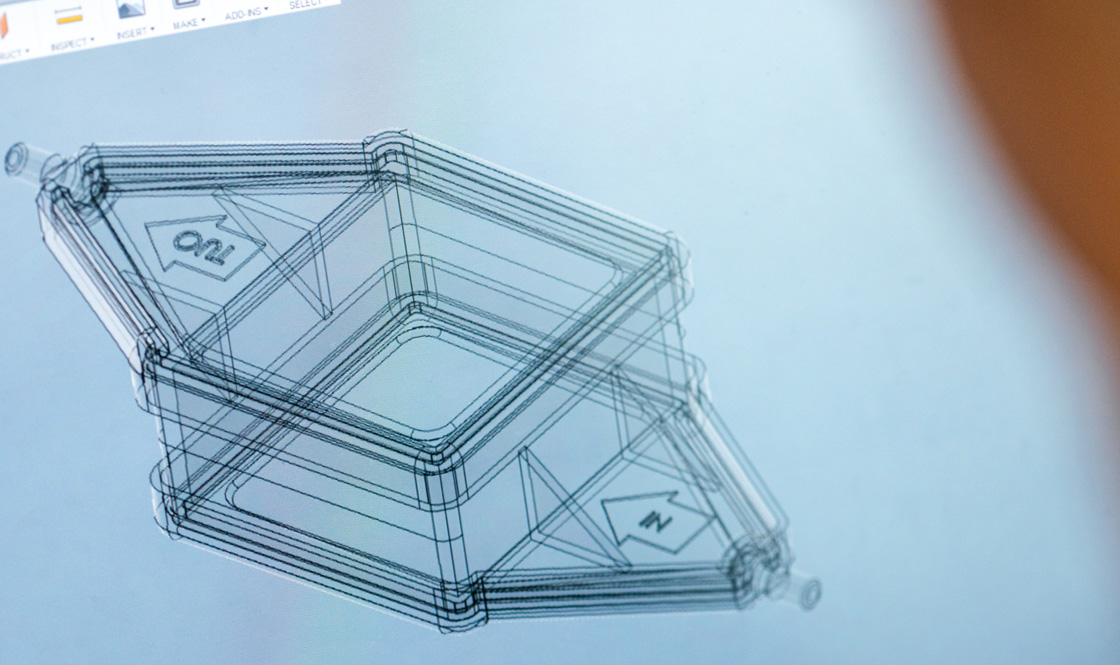

Once your idea is ready to move into a computer software it means that at this stage every detail must be defined. This computer model will be used to eventually be sent out to suppliers for prototype quotes or manufacturing quotes. This step can take place on a 3D CAD program such as Solid Works or Catia V5. Something very important to note here is that what you saw and approved on paper doesn’t always work in the real world. Always expect some sort of variations from what you saw in the initial concepts.

Don’t be frustrated as this is normal. During the modeling process you may not be in 100% satisfied with what the mechanical designers have done for you but they will work with you to make the necessary viable tweaks in order to ensure you are completely pleased.

When your idea becomes tangible

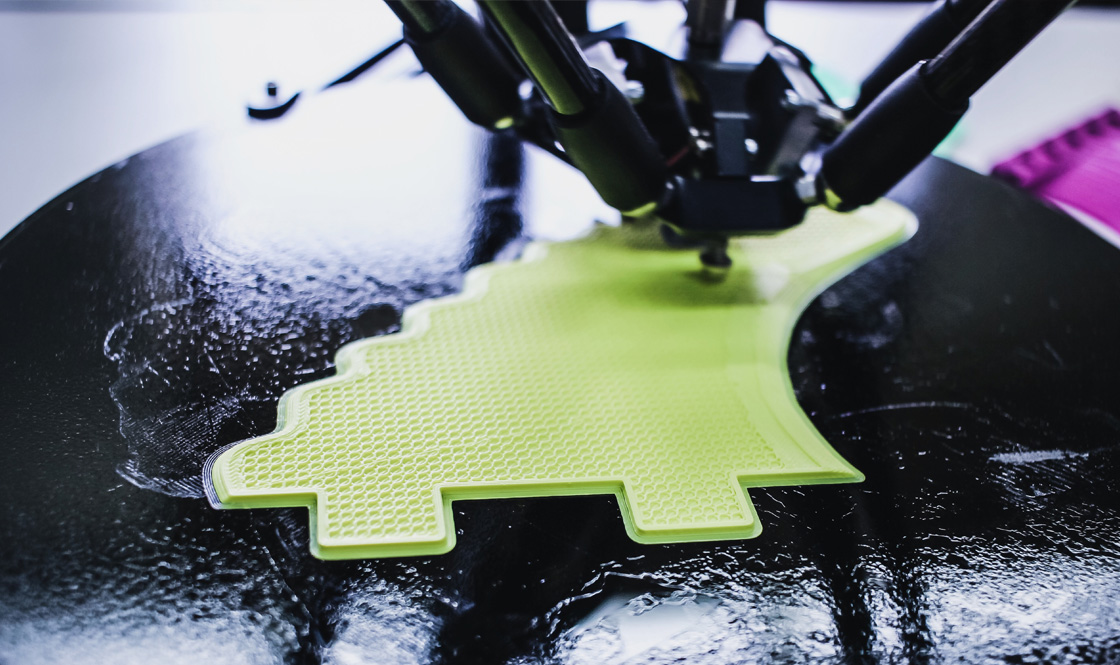

During the prototyping process your idea may come out of a 3d printer, a mould or maybe it was sewn. This is one of the most exciting moments of the design development process when you get to see your idea and actually touch it.

Here you get to hold it and feel it and discover the ergonomics of the product! Remember that prior to this process you had only seen your idea as a 3D digital concept and were only able to imagine how it would feel. Once it takes physical form, there may need to be slight changes carried out, once, twice or more. As part of this process, our mechanical designers have to make changes and 3D-print your model again to make sure you are satisfied.

When it’s finally ready to come to life

During the previous stage of the 3D model, the mechanical engineers made sure you had a prototype that would be easy to tweak and ready to print, but once you are ready to manufacture they have to go back to their CAD drawing and make a production-intent design that can actually be manufactured. Wall thickness, drafts, steel safe conditions, tolerances, and material selection is their priority. This phase takes a lot of time as this is the most critical part of making your idea come to life.

Once this process is complete the CAD drawings are sent to manufacturers for quotes. Once you decide which company will manufacture your idea they will send some pre-manufacturing samples. Yes, you have to pay for shipping costs. Even after we have these initial parts there can still be unexpected issues to resolve. This is very common and takes time to prefect. Expect multiple communications back and forth between our team and the manufacturer’s team and sending several sets of samples until the product is finally ready to go!

Still to cover in our next blogs are the things you wish you knew before patenting your idea and designing your ideal packaging for your product. So much that we can’t cover it all here. Stay tuned and check our next blogs but in the meantime stay calm and enjoy these first steps.

Recent Comments