How CNC Machining Improve Manufacturing and Product Design

In the dynamic world of product design and manufacturing, CNC (Computer Numerical Control) machining stands out as a cornerstone of modern production techniques. This technology, which automates the control of machine tools using a computer, has revolutionized how products are designed and manufactured. In this article, we delve deep into the world of CNC machining, exploring its intricacies, benefits, and the transformative role it plays in the industry.

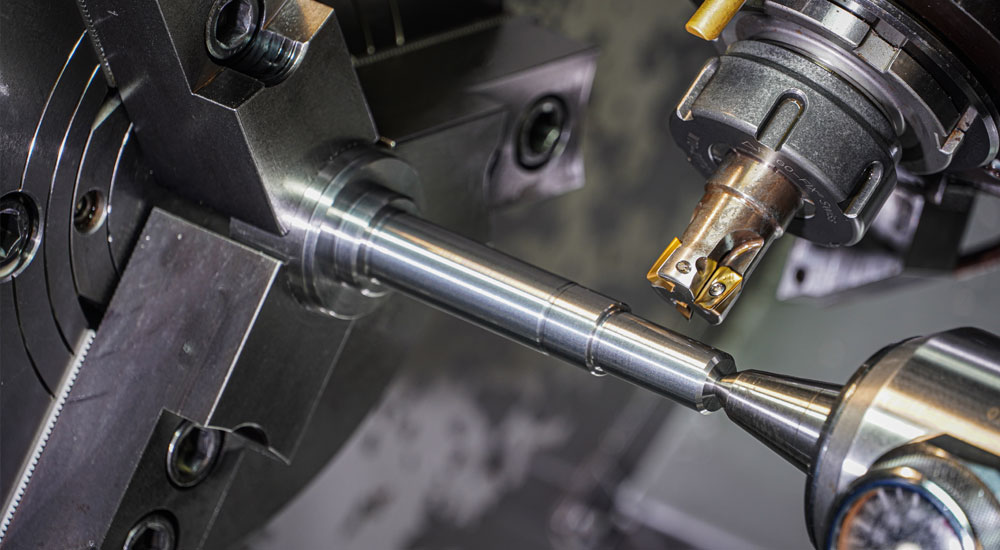

CNC machining is a subtractive manufacturing process that uses computerized controls to operate and manipulate machine tools. This innovative technology, which includes tools like lathes, mills, grinders, and routers, allows for the creation of complex parts and components with high precision.

The history of CNC machining trace back to the 1940s and 1950s, evolving from the traditional numerical control machines. Over the years, advancements in computer technology have significantly enhanced its capabilities, making it a critical component in modern manufacturing.

What is CNC Machining?

CNC machining is the process of using computer-controlled machine tools to create or modify parts and components. It is a vital tool in the arsenal of modern manufacturing, offering unparalleled precision and efficiency.

At its core, CNC machining is the automated control of machining tools by a computer. It enables the precise manufacturing of complex parts and is widely used in various industries, including aerospace, automotive, and healthcare.

A typical CNC machine comprises several key components, including a controller, machine tool, and a workpiece. The controller is the brain of the machine, executing instructions sent from a computer program. The machine tool performs the actual cutting or shaping of the material, and the workpiece is the material being machined.

How Does CNC Machining Work?

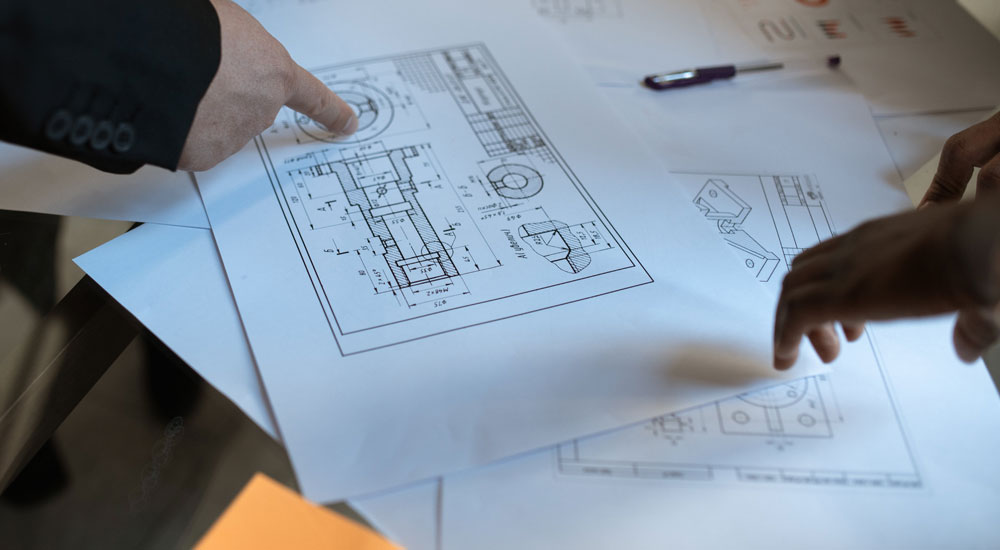

The CNC machining process begins with the creation of a 2D or 3D design using CAD (Computer-Aided Design) software. This design is then converted into a CNC program, which guides the machine in fabricating the part.

Designing the Part: Using CAD software, the desired part is designed.

Converting to a CNC Program: The CAD design is converted into a CNC program.

Setting up the Machine: The CNC machine is prepared with the correct tools and material.

Machining the Part: The CNC machine follows the program to create the part.

Quality Check: The finished part is inspected for accuracy and quality.

The Advantages of CNC Machining in Product Design

CNC machining offers several advantages in product design, contributing significantly to the efficiency and quality of the manufacturing process.

One of the most notable benefits of CNC machining is its precision and accuracy. CNC machines can produce parts with tight tolerances, ensuring consistency and high-quality output.

CNC machining offers tremendous flexibility in design. It can produce parts with complex geometries that would be difficult or impossible to achieve with traditional manufacturing methods.

CNC machines operate at a high speed and can work continuously without breaks, significantly increasing production efficiency.

While the initial investment in CNC machinery can be high, its efficiency and precision lead to reduced waste and lower long-term costs.

How Does CNC Machining Improve Precision in Product Design?

CNC machining’s precision is achieved through its ability to follow exact instructions from a computer program. This results in consistently high-quality parts with intricate details.

Why is Flexibility Important in Product Design and How Does CNC Contribute?

Flexibility in design allows manufacturers to quickly adapt to market changes and customer demands. CNC machining supports this by enabling the production of a wide range of designs without the need for extensive tool changes.

Material Considerations in CNC Machining

The choice of material is crucial in CNC machining, as it impacts the quality and suitability of the final product.

CNC machines can work with a variety of materials, including metals like aluminum and steel, plastics, and composites.

Selecting the right material involves considering factors like strength, heat resistance, and cost. The choice depends on the intended use of the final product.

Metals in CNC Machining

Metals like aluminum and stainless steel are commonly used in CNC machining due to their strength and durability. Metal laser cutting is a technology used to cut or engrave metal materials using a laser. Laser cutters are often controlled by CNC systems, which allow for precise movements and complex cutting patterns.

Plastics and composites offer advantages such as lighter weight and corrosion resistance, making them suitable for certain applications.

CNC Machining Techniques and Their Applications

CNC machining encompasses various techniques, each suited for specific applications.

The most common CNC machining types include milling, turning, drilling, and grinding. Each technique has its unique applications and benefits.

Milling

Milling involves the use of rotary cutters to remove material from a workpiece. It is ideal for creating complex shapes and features.

Turning

Turning is a process where the workpiece is rotated while a cutting tool removes material. It is typically used for cylindrical parts.

Drilling

Drilling creates round holes in a workpiece and is often used in conjunction with other machining processes.

Grinding

Grinding uses an abrasive wheel to achieve a high surface finish or tight tolerances on a workpiece.

Designing for CNC Machining: Best Practices

Designing for CNC machining requires consideration of the capabilities and limitations of the process.

Key Design Tips for Optimal CNC Machining

Understand Material Properties: Choose materials that best suit the application.

Optimize Design for Machining: Simplify designs to reduce machining time and cost.

Consider Tolerances: Design parts with tolerances that CNC machines can achieve.

Understanding Tolerances in CNC Machining

Tolerances refer to the allowable variations in dimensions and are critical for ensuring that parts fit together correctly.

Design Complexity and CNC Machining

Complex designs can be achieved with CNC machining, but they require careful planning to ensure manufacturability.

The Role of CAD and CAM in CNC Machining

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software play a pivotal role in CNC machining.

Explanation of CAD/CAM Software in CNC

CAD software is used to design the parts, while CAM software converts these designs into CNC programs.

Benefits of Using CAD/CAM in Design and Manufacturing

CAD/CAM software streamlines the design and manufacturing process, reducing errors and improving efficiency.

Case Studies: Successful Products Designed with CNC Machining

CNC machining has been instrumental in the success of numerous products.

- Aerospace Components: Precision parts for aircraft.

- Automotive Parts: Customized components for vehicles.

- Medical Devices: Custom implants and surgical tools.

Challenges and Limitations of CNC Machining

While CNC machining offers many advantages, it also has its challenges and limitations.

High Initial Cost: Offset by long-term savings in efficiency and waste reduction.

Limitations in Material Choice: Selecting the right material for the desired outcome.

Complexity of Design: Balancing design complexity with manufacturability.

Overcoming Material Limitations

Choosing materials that balance cost, performance, and machinability is crucial.

Dealing with Design Constraints

Understanding the capabilities of CNC machining helps in navigating design constraints effectively.

Future of CNC Machining in Product Design and Manufacturing

The future of CNC machining is bright, with continuous advancements in technology.

Trends and Innovations

Emerging trends in CNC machining include automation, increased precision, and integration with AI and IoT.

Predictions for the Future

The integration of CNC machining with other technologies is expected to further enhance its capabilities and applications.

FAQs in CNC Machining for Product Design

CNC machining is a topic of interest for many in the industry.

Commonly Asked Questions and Answers

Q: What is the accuracy of CNC machining?

A: CNC machines can achieve high levels of accuracy, often within thousandths of an inch.

Q: Can CNC machines work with any material?

A: While CNC machines are versatile, they work best with certain materials like metals, plastics, and composites.

Resources and Further Reading

For those interested in delving deeper into CNC machining, several resources are available.

Books: “CNC Programming Handbook” by Peter Smid.

Courses: Online courses on platforms like Coursera and Udemy.

Conclusion

CNC machining is a vital component in the field of product design and manufacturing. Its precision, efficiency, and flexibility have made it an indispensable tool in creating complex and high-quality products. As technology continues to advance, the role of CNC machining is set to become even more significant, shaping the future of manufacturing.

Recent Comments