Tube Laser Cutting Machine in product design | Ultimate Guide

Imagine effortlessly slicing through complex shapes and materials, making even the most intricate designs a reality with just a few clicks. Welcome to the world of tube laser cutting machines, where innovation meets precision to create flawless results in a fraction of the time. Dive into this ultimate guide and discover the technology, advantages, applications, and more of this game-changing tool.

What are Tube Laser Cutting Machines

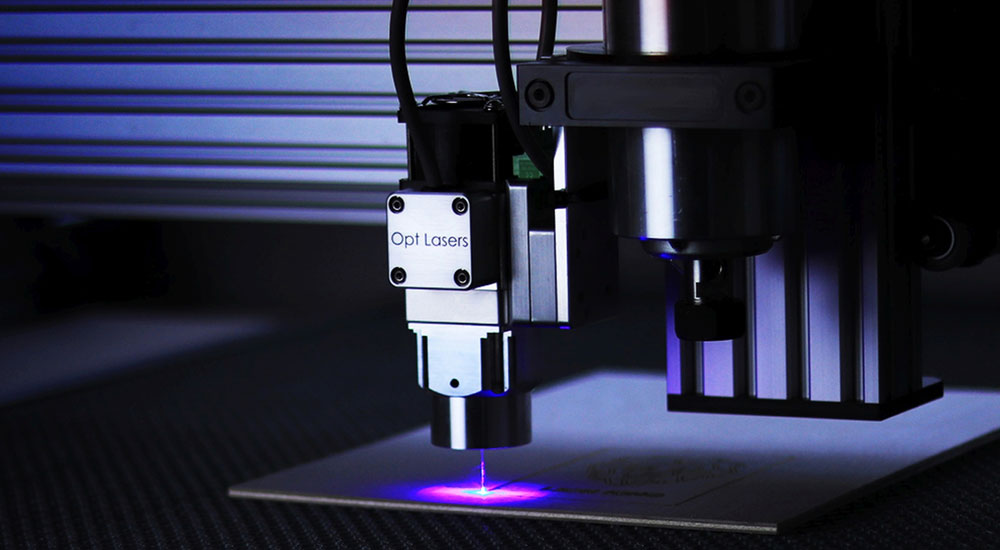

Tube laser cutting machines are advanced, computer-controlled devices that use high-powered lasers to cut, engrave, or etch various materials like metal, plastic, and wood. These machines utilize a concentrated beam of light, which focuses on the workpiece to achieve high-precision cuts with exceptional speed and accuracy. The versatility and efficiency of tube laser cutting machines have made them an indispensable tool in numerous industries, including automotive, aerospace, construction, and furniture design.

The Advantages of Tube Laser Cutting Machines

Tube laser cutting machines offer a plethora of benefits over traditional cutting methods. Let’s explore the main advantages that make these machines indispensable in many industries:

Unparalleled Precision and Accuracy

Tube laser cutting machines deliver exceptional precision and accuracy, allowing for intricate cuts and detailed designs that are impossible to achieve using conventional cutting methods. This precision results in less material waste and higher product quality.

Speed and Efficiency

The automation and speed of tube laser cutting machines dramatically reduce the time required to complete a project. As a result, companies can increase their production capacity, shorten lead times, and enhance their competitiveness in the market.

Versatility

Tube laser cutting machines can work with a variety of materials, including metal, plastic, and wood, making them suitable for various industries and applications. Moreover, these machines can be easily adjusted to handle different shapes and sizes, adding to their versatility.

Reduced Material Waste

The precise cutting capabilities of tube laser cutting machines lead to minimal material waste. This not only reduces production costs but also promotes sustainability by reducing the environmental impact of the manufacturing process.

Enhanced Safety

Tube laser cutting machines are typically enclosed, which helps protect operators from the hazards associated with traditional cutting methods, such as sparks and debris. Additionally, the automation of these machines reduces the risk of human error and the likelihood of workplace accidents.

Some advantages of tube laser cutting machines include:

Unparalleled precision machining and accuracy

Speed and efficiency

Versatility

Reduced material waste

Enhanced safety

Applications of Tube Laser Cutting Machines

The versatility and efficiency of tube laser cutting machines have made them popular in various industries, including:

Automotive

Tube laser cutting machines are used to produce lightweight, high-strength components, such as chassis and suspension parts. This technology allows for the creation of complex geometries and streamlined designs, which contribute to improved vehicle performance and fuel efficiency.

Aerospace

In the aerospace industry, precision and quality are paramount. Tube laser cutting machines help achieve these standards by providing accurate and intricate cuts on critical components like airframes, engine parts, and landing gear.

Construction

Tube laser cutting machines are employed in the construction industry for creating structural components, such as beams, columns, and trusses. These machines enable the production of customized, intricate designs that enhance the aesthetic appeal and functionality of buildings.

Furniture Design

In furniture design, tube laser cutting machines are used to create intricate patterns and shapes on various materials, including metal, wood, and plastic. This technology enables designers to produce one-of-a-kind pieces with stunning visual appeal.

Selecting the Right Tube Laser Cutting Machine

When choosing a tube laser cutting machine, several factors should be considered to ensure that the machine meets your specific needs and requirements. Here are some essential aspects to take into account:

Material Compatibility

It is crucial to choose a machine compatible with the materials you plan to work with. Different machines are designed for specific materials, so ensure the machine you select can efficiently handle your desired materials, such as metal, plastic, or wood.

Cutting Capacity and Size

Consider the size and capacity of the machine, taking into account the dimensions of the workpieces you will be cutting. Ensure the machine can accommodate the maximum length, width, and thickness of the materials you intend to use.

Laser Power

Laser power plays a vital role in cutting speed, efficiency, and material thickness capabilities. Higher-powered lasers can cut through thicker materials and at faster speeds. Assess your production needs and choose a machine with the appropriate laser power to meet your requirements.

Software and Control System

A user-friendly software and control system are crucial for efficient operation and ease of use. Look for machines with intuitive interfaces and software that offer advanced features, such as nesting, kerf compensation, and remote monitoring.

Budget and Cost-effectiveness

When selecting a tube laser cutting machine, consider the initial investment, as well as the long-term costs, such as maintenance, consumables, and energy consumption. Weigh the benefits of the machine against its total cost to determine its cost-effectiveness and ensure it fits within your budget.

Maintenance and Safety Tips for Tube Laser Cutting Machines

Proper maintenance and safety practices are essential for the efficient operation and longevity of tube laser cutting machines. Here are some tips to help you maintain your machine and ensure safe operation:

Regular Maintenance and Inspection

Conduct routine inspections and maintenance checks to ensure that all components are in good working condition. Replace worn or damaged parts as needed, and keep the machine clean and free from debris.

Proper Ventilation and Fume Extraction

Laser cutting generates fumes and gases that can be harmful to operators and the environment. Ensure your workspace has proper ventilation and invest in a fume extraction system to maintain a safe and healthy work environment.

Training and Operator Safety

Provide adequate training for all operators to ensure they understand the machine’s functions and safety features. Operators should wear appropriate personal protective equipment (PPE), such as safety glasses and heat-resistant gloves, when working with the machine.

Emergency Preparedness

Develop an emergency plan and ensure that all operators are familiar with the procedures. Install safety equipment, such as fire extinguishers and emergency stop buttons, in easily accessible locations around the machine.

Conclusion

Tube laser cutting machines have revolutionized the manufacturing industry in product design by offering unparalleled precision, speed, versatility, and safety. These advanced machines have found applications in various sectors, including automotive, aerospace, construction, and furniture design. By selecting the right machine for your needs and following proper maintenance and safety practices, you can harness the power of tube laser cutting technology to boost your productivity and achieve outstanding results.

Recent Comments