Design, Engineering, Prototyping and Manufacture

Product Development and How We Bring Ideas to Life

If you are designing a product that you plan to manufacture and sell, you are probably wondering what the different stages of the design process are. These steps will help you understand how to design a product, where you are in the design process, and where to get any assistance you might require.

Product Design Ideation: Your product idea comes from identifying a problem and devising a solution for it. Try to capture the essence of your idea, its main purpose, the problem you want to solve, and the form you want it to have.

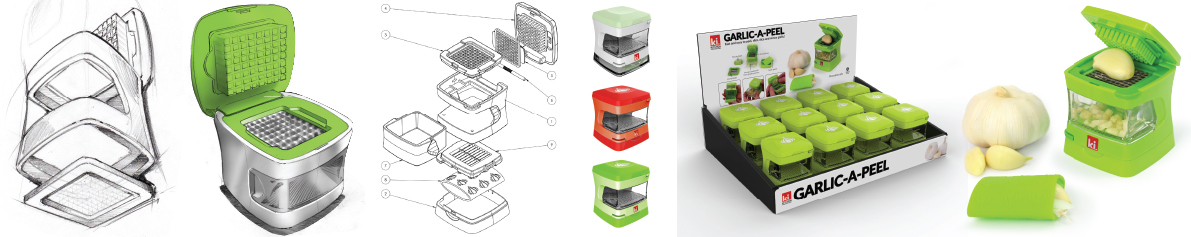

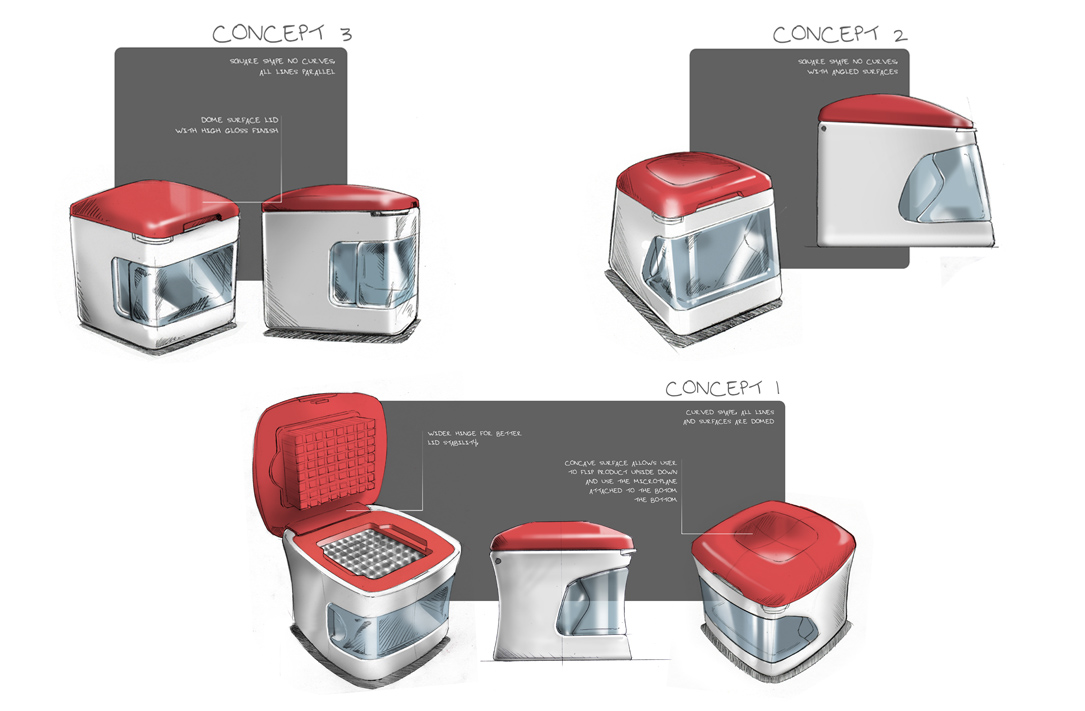

Detailed Hand Drawings: At Spark Innovations we may present hand drawings and some initial CAD drawings. At this point, colours can be defined and the overall form, look, and feel can be finalized. If your design is in the detail stage, it may be ready to go to 3D software.

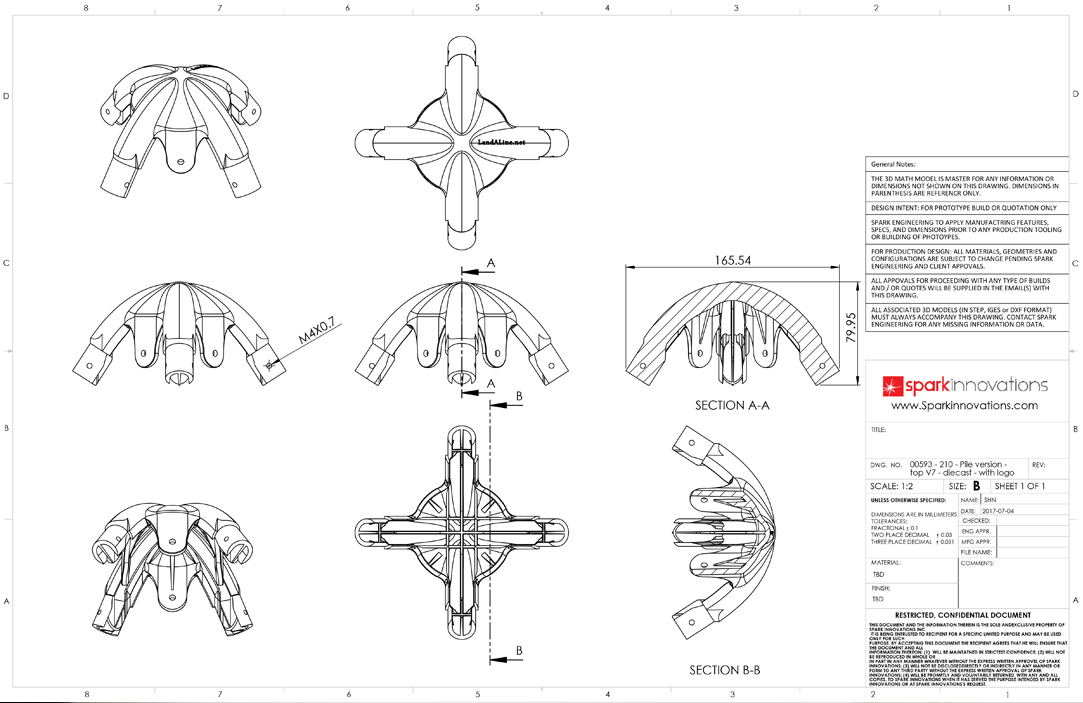

Mechanical Drawings: Here, measurements are defined and the initial stages of manufacturing and tooling are thought out. Mechanical engineers have to be able to create moulds from these drawings, so it is very important to have every detail of your idea figured out.

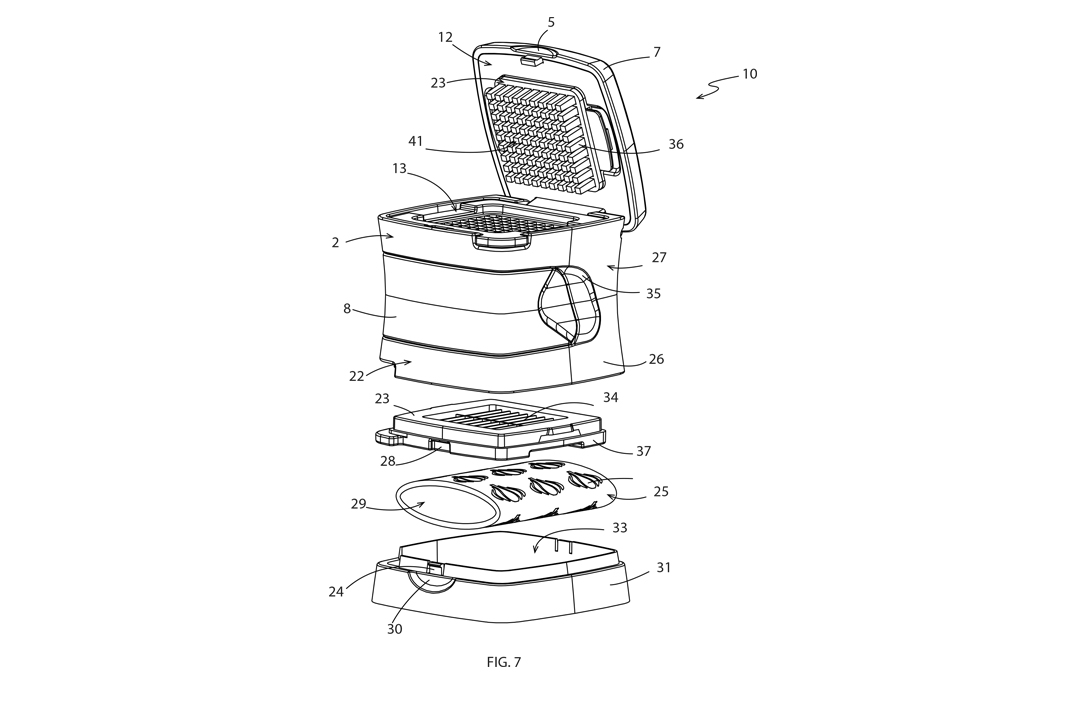

Patent: Some inventions have features, core ideas, or functionality to get patented. If it is possible for your idea to be patented, try protecting it with either a utility or design patent. It may be possible to license your product to a large company or create a successful business from it.

3D printing or prototyping: At Spark we use the PolyJet Objet 30, a high-resolution 3D printer. With this 3D printer, we are able to build models and prototypes featuring ultra-precise details. In some cases, if the idea is large enough it has to be handmade or tooled up in China.

Sample Products: A small run can help you ensure the final products have no issues. If any problems exist, this is the time to correct them. Any modification to a part or mould should be corrected before placing a large order.

Final Product: Correcting any issues can take time and involve considerable back-and-forth with the manufacturer, but once you are confident the product is ready, it’s time to place your final order.

We hope this brief guide to product design has been helpful and inspires you to turn your idea into a tangible product. Whether you are at the beginning stages, stuck in the middle, or almost at the end, our experts at Spark Innovations can help you bring your ideas to life.

Recent Comments