How do I get my prototype made?

You have a great idea and have decided to put time, energy, and some serious resources into making it a reality. What’s next? A prototype. You may be asking yourself:

Why do I need to complete or even develop a functioning prototype?

A prototype is the essential first step for transforming an idea into an actual, physical product.

If you are just getting started with your idea, a prototype is a great way to get the feedback you need to ensure you are creating an effective product. You can make prototypes in different stages as well. If finances are an issue, you can start by creating a very rough model. This can be the initial guide to define the exact size and proportion of the product. It can be made very quickly with materials you find around your own home. If you have allotted a bit of money to your prototype and are looking for a product development firm to help you, we still recommend that you begin with a rudimentary prototype. Even at its most basic, you can use this initial prototype to present your idea to the design firm and help everyone understand the product and how to take that prototype to the next level.

Prototypes are made for several reasons: testing a product to see if it really works; making sure the ergonomics and sizes are appropriate for the target market; for pitching or marketing purposes; and, finally, for manufacturing.

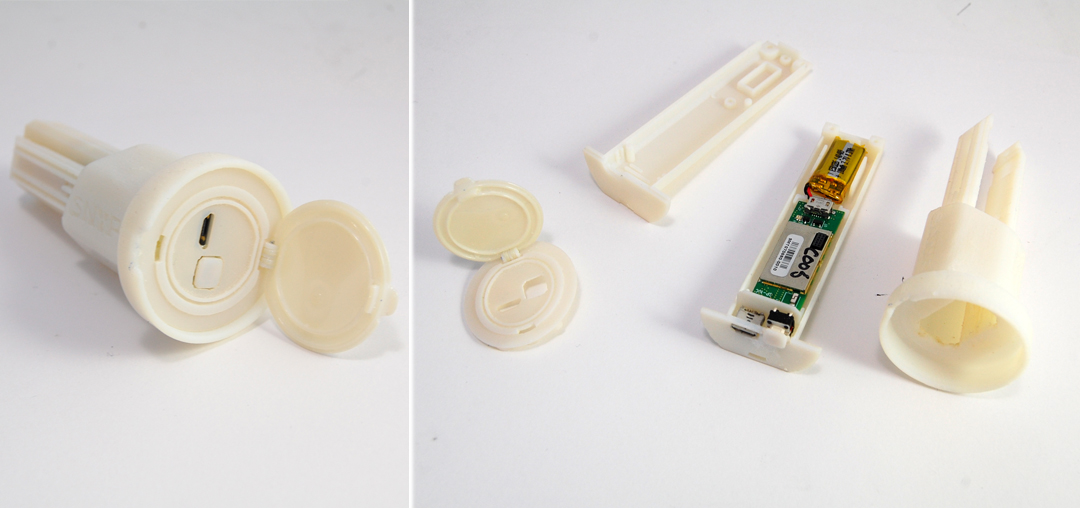

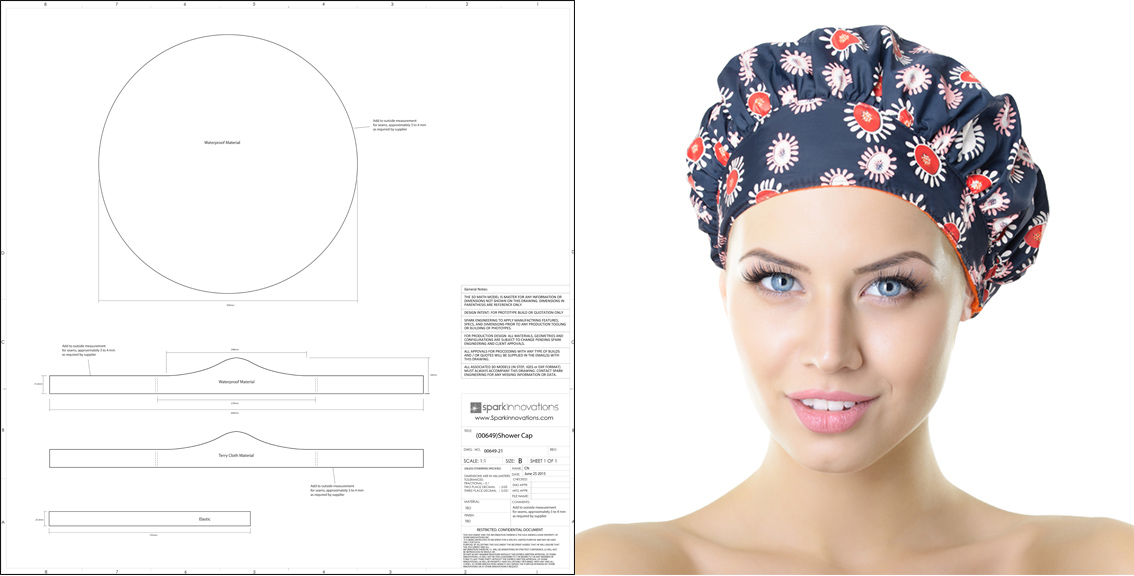

Below are two examples of 3d printed functioning prototypes that were used for marketing purposes, feedback and for pitching the idea to potential investors.

Recent Comments