Product Engineering for Product Development

If you have a great idea or invention and plan to move forward with product development, you may be looking into product engineering. When designing a new product there are many steps you have to follow to ensure a successful product launch. These steps are part of the product development process and include: research, industrial design with concept development, ergonomics & styling, engineering, prototyping, patenting (if it applies to your product), manufacturing, branding, and graphics and packaging. This list may seem overwhelming to some inventors. In some cases, inventors may skip a step or even try working on a few steps themselves to save money. If this is the case for you, keep in mind that there is one important step you cannot miss: product engineering.

1 905-833-5122

The Importance of Product Engineering

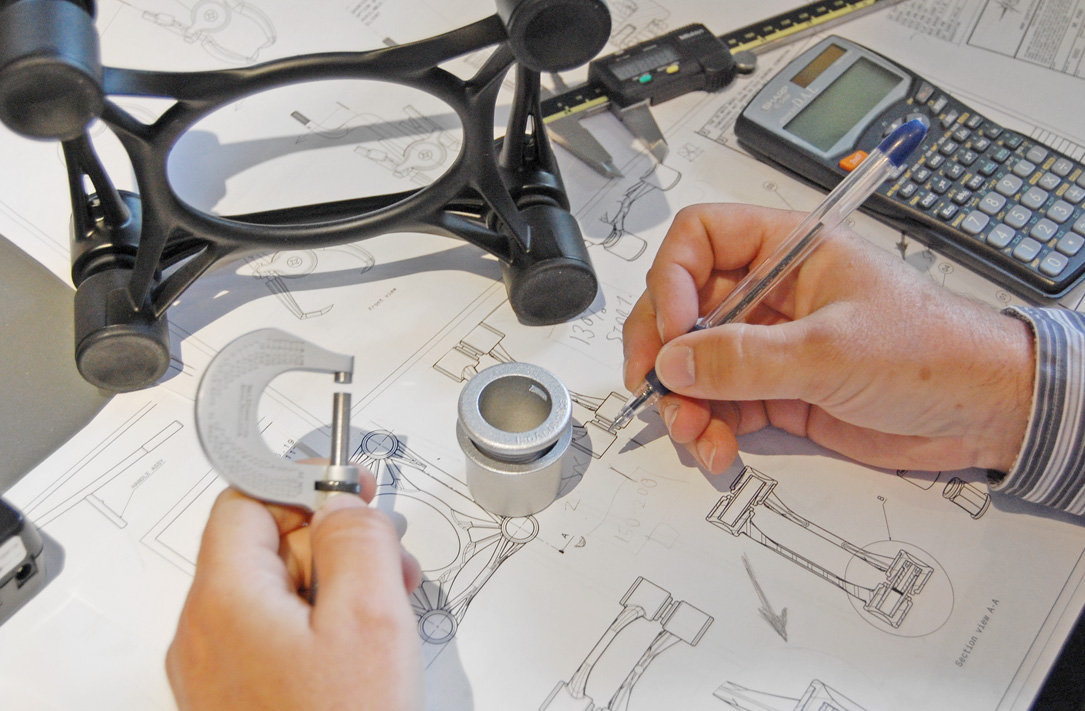

Any new idea or invention can be designed by its own creator or inventor but it will need important details defined by an industrial designer, mechanical engineer, or product engineering team that understands how products are assembled and manufactured.

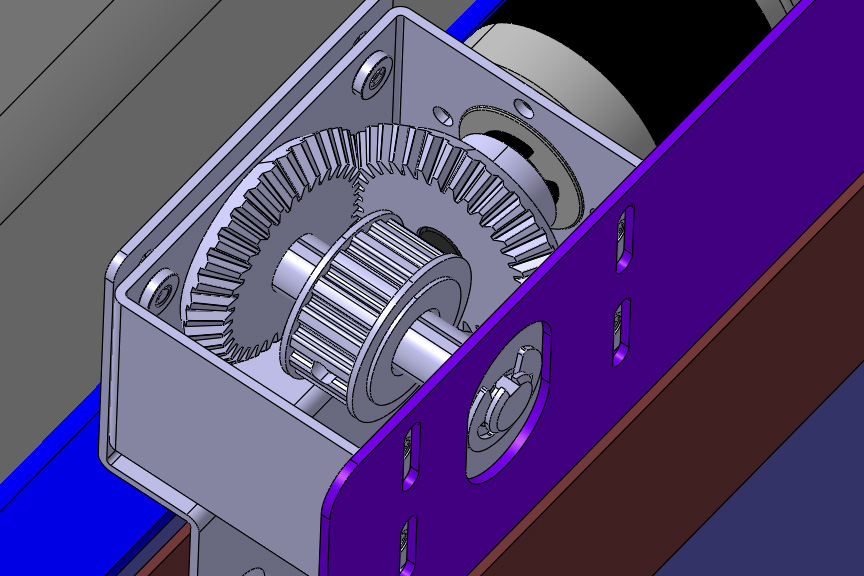

The product engineering team overseeing new inventions has a lot of different responsibilities. This team pays attention to production sequence details that lead up to a production line. A product engineering team designs a product in a 3D CAD program such as SolidWorks or Catia and ensures the product is feasible for both the user and the manufacturer. Proper communication with the manufacturer is essential to the successful development of a product.

Product Engineering and Cost Reduction of Products

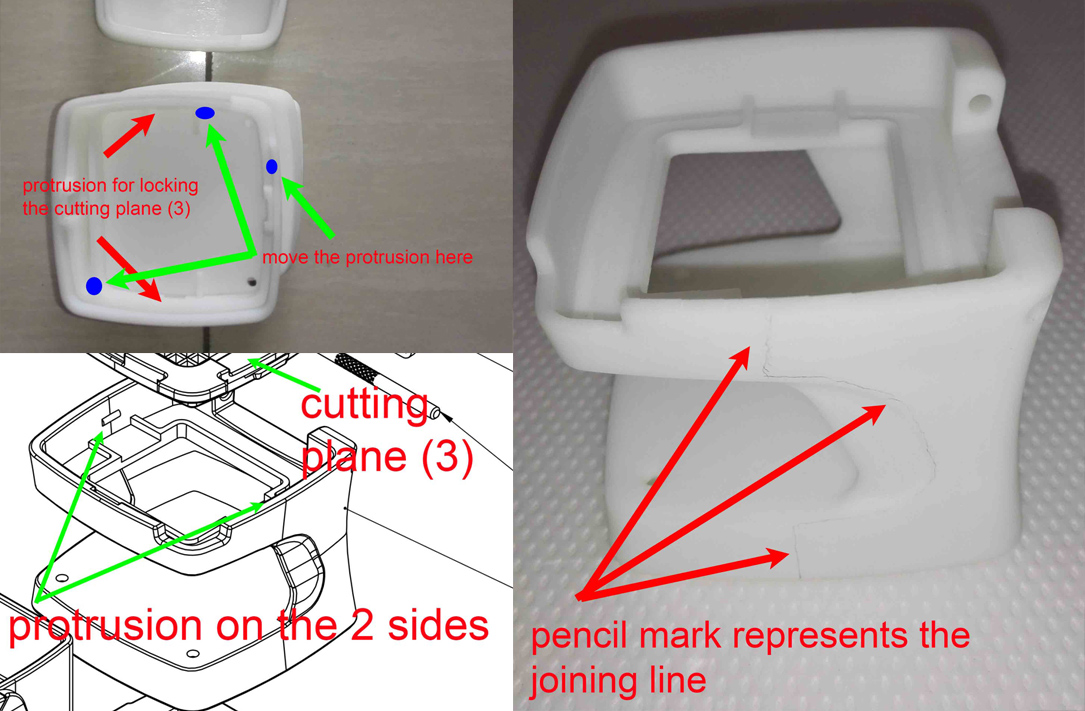

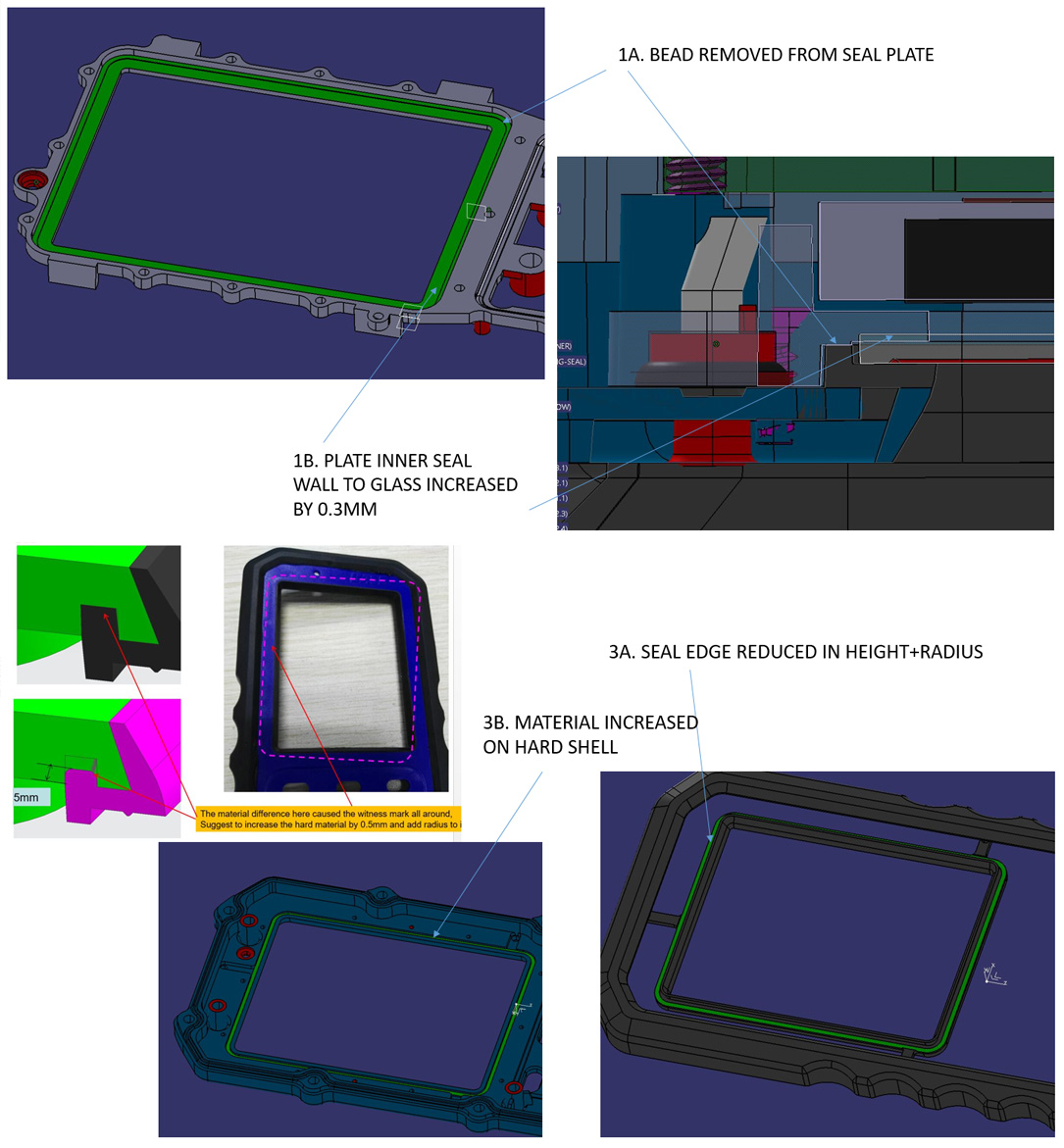

One of the most important details involved in product engineering is reducing costs. At Spark we take pride and have a great deal of experience in helping reduce the costs of your products without sacrificing the quality or aesthetics. Our detailed modelling and analysis enables us to find cost savings at various stages of the development process. How? With technology and expertise. Our 3D printer is a high resolution PolyJet Objet 30. We use it to build models and prototypes with ultra-precise details. The CAD drawings are used for tooling, manufacturing, and assemblies, and provide precise specifications for the mechanical components and all parts of the design. The product engineering team outlines how the components of your design are integrated together in a larger system and they look into details like wall stock, drafts, steel safe conditions, tolerances, and material selection to ensure that your product is meticulously designed. This level of detail will be reflected in the molds that are used to generate each of the parts of a design idea. This part of the process is the most crucial step in making an invention come to life.

Skip a step—which we don’t advise—or save some money and complete a few steps yourself, but leave the product engineering to professionals like our team at Spark Innovations. If you have a new idea, you need a product engineering team to bring it to fruition successfully. Contact us with any questions!

Recent Comments