The Product Design of the finger blade

Jacs Finger Blade

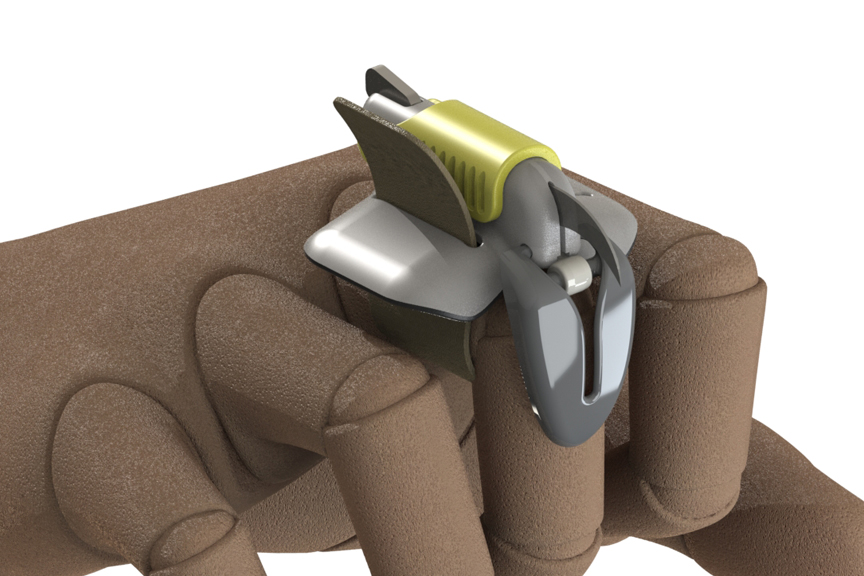

Our client has a background in the packaging industry. From years of experience he was always faced with lack of efficiency and productivity when working on a repetitive packing job. He approached Spark Innovations in search of a product with a blade that he wouldn’t have to put down each time he needed his hands and that would be safe enough wrap around his hand or fingers.

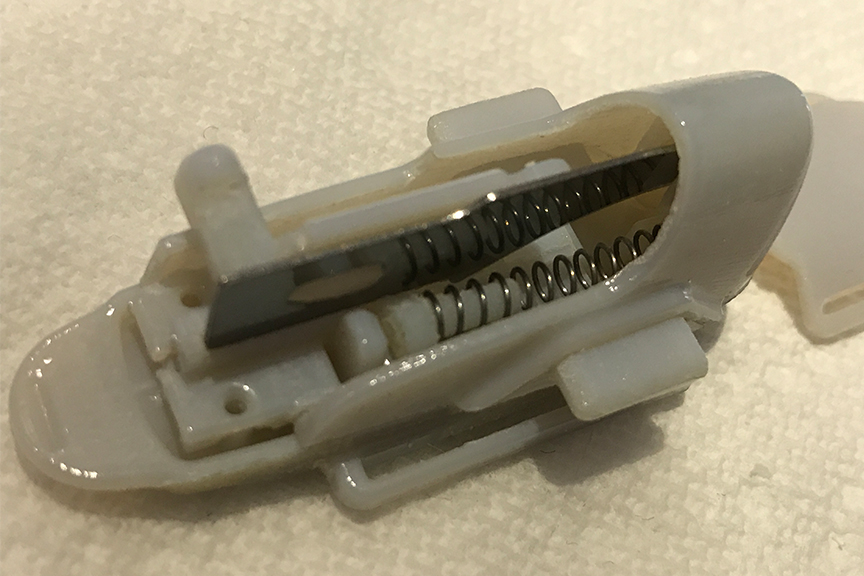

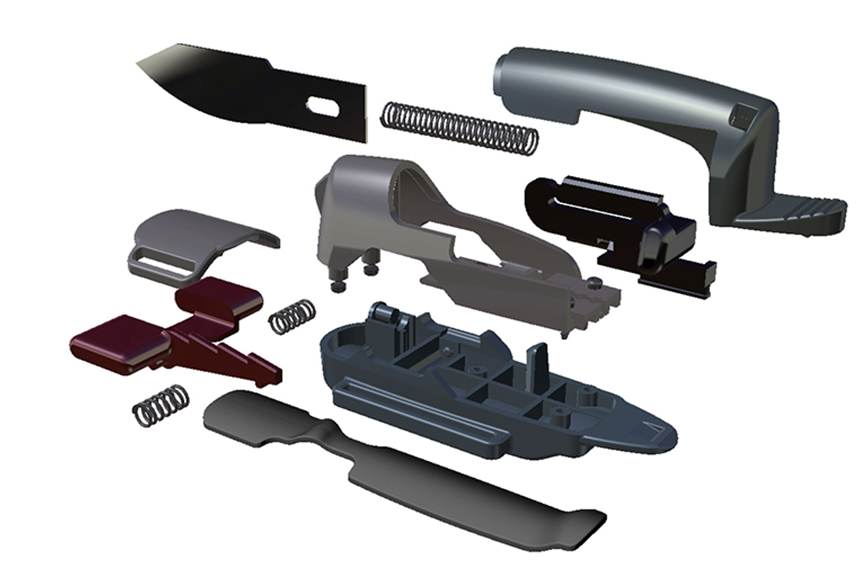

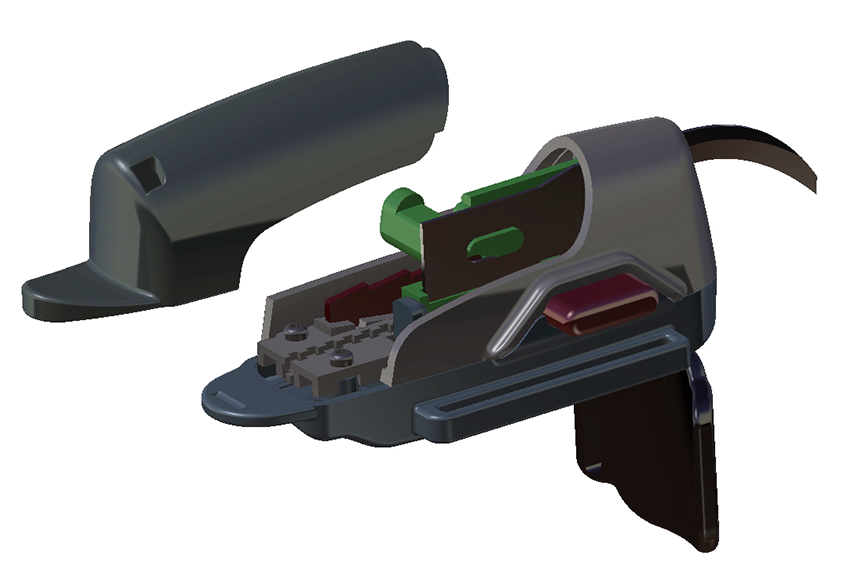

Spark Innovations provided Industrial Design concepts right through to the mechanical engineering validation and development for this very unique product. As it was put to the test many rounds of strategic prototyping and physical validation were required in order to have this product function exactly as intended by our client.

The FingerBlade allows for increased efficiency and productivity. Not having to constantly put down, pick up or search for your cutting tool, means enjoying continuous uninterrupted work flow. Users can empty the contents of their packages, write, type, talk on the phone and perform other tasks all while wearing their FingerBlade. In addition to more natural movement of the wrist, with a maximum blade depth setting of just over 1/2″ the FingerBlade helps reduce the chances of injury.

Never hold, drop, lose, reach or search for your cutting tool.

The JACS FingerBlade is a new cutting tool that fits on the users finger. Its not only used to open boxes & packages but also shrink & bubble wrapped packages and materials such as poly, paper, foam, rubber, cardboard and more depending on the material & thickness.

Spark then continued to support and see the “Finger-Blade” right through to a fully manufacturable and sellable item. Even some of the smallest and seemingly “simple” products provide the most challenges. Fractions of a millimeter can make or break the success of a product working properly, but Spark Innovations, as always, were up to the tasks at hand. Get yours Here!

Recent Comments