The Technology behind the Ball Cap Liner (BCL)

The Ball Cap Liner MISSION:

The BCL’s mission is to provide a solution for head safety in the ball sporting world. The ultimate goal, which the BCL has achieved, is to create headwear that has tremendous impact protection in a very thin package. The BCL provides a significant reduction in injury/head trauma with a revolutionary minimalist design that is light, comfortable, and practically invisible.

The Ball Cap Liner Design

With a sleek minimalist design but maximum impact protection, the BCL provides safety without sacrificing any normal functionality or comfort for the person wearing it. It fits to the head not the hat. The D3O foam molds/contours to every bump on the wearer’s head, meaning that even if the hat falls off, the protection stays on.

It is available in two models and two sizes: with Temple Protection and without Temple Protection; large and small. The BCL can fit under an adjustable ball cap or a one size larger fitted cap.

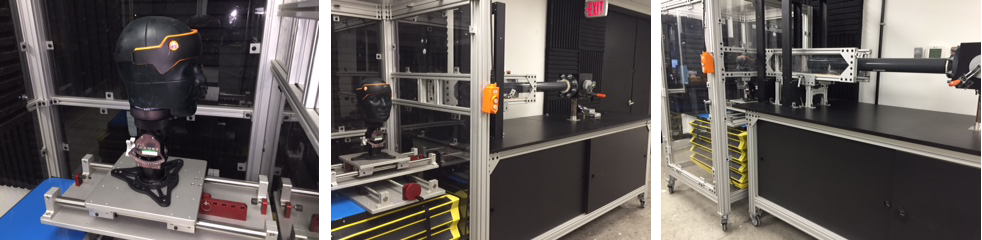

Laboratory Tested

The BCL has been rigorously tested. It passed the frontal impact standard for baseball and softball, as per ICS ballistic testing carried out in July 2015. Tests also showed proven significant side impact protection for glancing blows.

Technology

What makes it so strong? The Ball Cap Liner is made of a very thin polymer shell with a shock absorbing foam; two revolutionary new materials that are advanced enough to pass rigid safety standard tests.

What are they? D3O shock absorption foam and a space-age metal replacement plastic, both the result of groundbreaking innovations in materials technology.

D3o

D3O is a pioneering impact protection solutions company that licenses a range of unique patented smart materials. Their market-changing technology is used to produce a shock absorbing material that can be found in a range of products across the motorcycle, sport, footwear, electronics, military, and work gear sectors. Recently D3O signed an exclusive partnership with CCM Hockey Helmets.

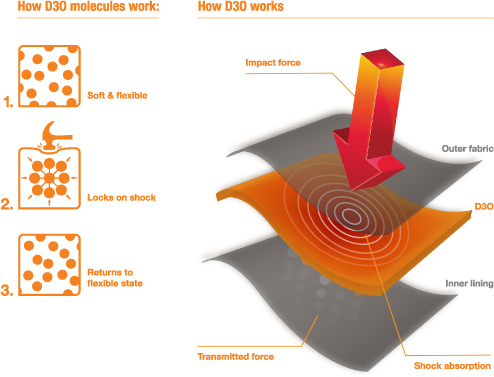

D3O® Shock Absorbing Technology

Here is how D3O® technology works: D3O® materials in their raw state flow freely when moved slowly, but on shock, lock together to absorb and disperse energy before instantly returning to their flexible state. This reaction is counter-intuitive: the greater the force of the impact, the more the molecules lock together and the greater the protection.

D3O does not get hard when hit, but the molecules lock together to absorb and spread the force, significantly reducing the effect of any impact. D3O reacts uniquely to each environmental force, providing a different level of impact protection at high speeds compared to low speeds. D3O is perfect for applications where weight is a primary requirement: the unique molecular properties allow it to remain thin and flexible, while still providing optimum protection against impact.

Metal Replacement Plastic

Metal replacement plastic is designed as a high performance resin. This material is the specialist for metal replacement using technologically advanced polyamides to achieve weight and cost savings. Polyamides are among the most versatile and high-performing of plastic materials and a proven material for metal replacement plastic.

The specialized plastic resin is reinforced with glass fibers for high levels of stiffness, strength, and impact resistance. The material offers little change in property values after absorption of moisture. With low dampness and water absorption and great dimensional stability and low warpage, metal replacement plastic is ideal for athletes who play hard and work up a sweat!

Recent Comments