Unusual Things You Didn’t Know You Could Make With a Multicolor 3D Printer for your next New Product Design

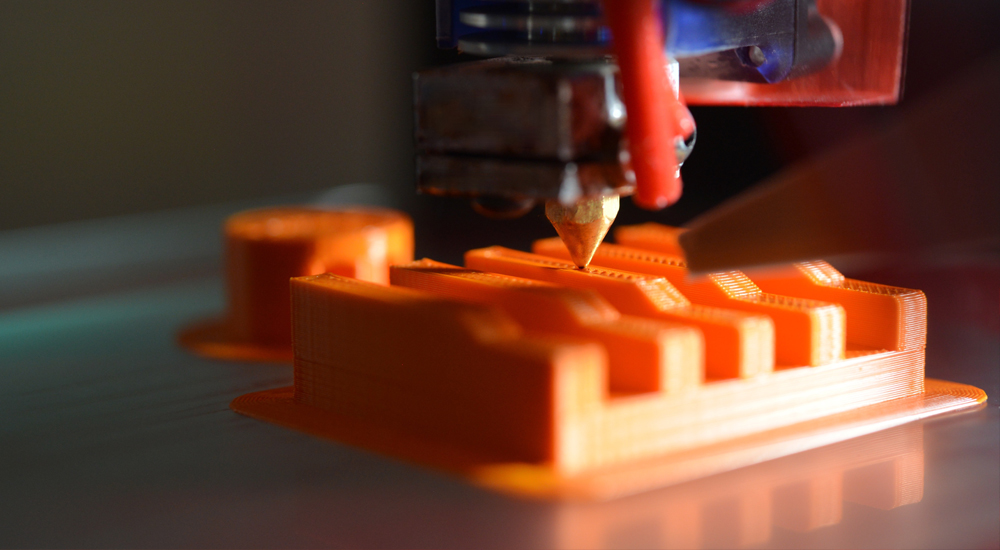

Whenever you speak of the future of technology, you are always inclined to bring up topics of electric cars, robotics, and 3D printing technology. 3D printing technology never ceases to make headlines, as it proves more useful in big-time manufacturing industries and our daily lives.

The technology has been used to make toys, jewelry, and simple cutlery designs. These simplistic designs can get boring over time. It would be best to venture into unorthodox products that embrace the power of 3D printing. Here are several things you could make with your 3D printer.

A Battery Missile Launcher

Talk about a cool toy that makes use of dead batteries! No need to worry about the designs as they are available on the internet. You need to download one, make the necessary changes, and start printing it out. Your configurations will revolve around how many batteries you wish to fit into your toy and to what degree it can revolve.

The Gravity Broom holder

This design aims to make your broom storage much more manageable. The broom holder uses the weight of the broom to set the broom straight and rest on the holder. The holder also contains a gear as a clamp that locks the broom in place.

The rack and the gear are usually separately 3D printed, and assembling is the final stage. The material used in their printing is Polylactic Acid filament, which is renewable.

A Cookie Box

A printed-out cookie box has many advantages. First, you can make a unique design, making the box all the more special. The material used to print out the cookie box is also safe for storing foodstuff.

If you are not creative, you can easily choose from the various cookie box designs available on the internet. For instance, the standard Oreo cookie box uses a multicolor 3D printer to mimic an exact Oreo. If you didn’t know better, you would mistake the box for the real stuff.

Business Cards

Printing out your business card is truly the epitome of unusual in 3D printing. Such a card will impress your clients, mainly if you deal with commercial 3D printing. Unlike the regular card, this card does not get wet, is not easy to lose, and is light.

Adding multiple colors will, indeed, make things more interesting. In the fun of making the print-out, do not forget to put all relevant details on your card.

A Squeeze Drill

More robust than it looks, a squeeze drill will be a nice challenge to make using your 3D printer. This drill will be excellent for making light drills; since it is mechanical, you will not need to worry about electric consumption.

To make the squeeze drill, you need a drill bit, several screws, and a spring. You will need to create a prototype using your computer design application for your printer to start its work.

A camera

Imagine making your working camera in a matter of minutes! Yes, a 3D printer is equipped to make your pinhole camera. You will only need to make a design of your camera, buy a Mamiya press lens, print the shell, and assemble the whole thing. You are sure to spend less money than you would have to buy a brand-new camera.

A Telescope

A telescope may look complicated to design, but it is, in fact, relatively easy. There are designs to leverage from the internet, and if you wish, you could make changes to them.

Building a telescope from a 3D printer is one of the most fascinating things to do, especially when you start using it to discover the world above. The printed telescope will also cost much less than a store-bought telescope.

A Violin

Not just any violin, an electric violin! The design of this instrument can get tricky, but if done correctly will be fulfilling to have. The violin will cost you a fraction of what you would spend on buying an original violin and will provide a great learning experience of using your 3D printer. Your printed violin is also sure to be much more colorful than the instrument in your local music shop.

A Coffee Maker

Imagine waking up to coffee from a coffee maker you’ve made! It would make your mornings all the more worth looking forward to.

Building a design for your coffee maker is not as easy as the violin project. It will, however, be worth the try as the final product will save you on the cost of buying a coffee maker.

What are the Advantages of 3D printing?

Below are the reasons people use 3D printing.

Easy on the Pockets

The material used to make 3D prints is relatively cheap compared to buying your intended item. Also, looking into the time taken to print out your project, it is safe to say that it is cost-effective.

The cost of buying a 3D printer is relatively high, which can be averted by sending your project designs to companies offering 3D printing services.

Excellent Material Properties

The materials used for 3D printing are PLA and ABS filaments. These filaments are strong, durable, resistant to heat, and lightweight.

When molten, the materials are also easy to mold. The PLA, for instance, is also biodegradable. Such properties make the materials desirable to use in areas required to be fast and highly efficient.

A Fast Production Time

A 3D printer can print out complex designs very fast. The printer does not usually need assistance from humans during production.

All you need is to feed the design into the computer connected to the printer, and everything else is automated. Such features make 3D printing desirable even to big manufacturing companies as it means meeting customer demands on time.

Less Wastage

A 3D printer will use only the material required to make a design. It means less time is taken to polish the final product (if any).

If the design needs to change, the 3D printer will provide features for that change. For this reason, 3D printing technology is gaining more points with companies that are cutting the cost of materials.

Accessibility

3D printers are becoming more available to the public as the technology impressively makes life easier. The printers are also less expensive than they were during the initial stages of their discovery. Shipping costs of the printer are also not as expensive, as manufacturing companies competitively try to make more sales of the 3D printer.

Disadvantages of 3D Printing Technology

Below are the challenges you’ll face using 3D printing technology.

Few materials

There are only two widely available materials certified for 3D printing. The PLA and ABS filament have different features, with the PLA preferred for biodegradability. These materials are also not widely available compared to metal and ceramics.

Large Projects are Hard to Print

Many 3D printers will only print up to a specific size. Certain projects will have to be printed in bits and assembled afterward. The time taken to print the parts of a project separately and assemble them is therefore highly increased, and there is also increased labor for assembly.

Loss of Jobs

Since 3D printers are highly automated, there is less need for human labor. It means that many people are at risk of losing their jobs. The rate of poverty and crime will inevitably rise as these vices go hand in hand with unemployment.

Inaccurate Designs

Due to problems such as vibrations and low tolerances, your 3D printer could prove not as great as you thought. Although such problems are easy to fix, they will cost you your material and time if you restart the project. To ensure such issues do not occur, one must perform regular maintenance checks before they start printing.

Static Cost Even with Large-Volume Production

You would think that the cost of production using a 3D printer would decrease with the production of a large volume of goods. It is, however, not the case as the cost of production remains constant.

It is also unlike other techniques, such as injection molding, which would guarantee cost-effectiveness with the increased sum of goods you produce.

Counterfeits

3D printing allows criminals to produce counterfeit products for the same price as the original. 3D printers’ accuracy will make it much more difficult to differentiate between the original and the counterfeit.

Even though 3D printed projects are considered vital, the lack of a well-laid-out design will reduce strength and may cause harm to the user.

Final Thoughts

3D printing technology has undoubtedly made life easier as making things

with the printer is easier. Due to advancements in design applications such as CAD and CAM, printing more complex designs is much easier, faster, and cost-effective.

Research shows that we have only tasted the tip of the iceberg of what 3D printing can do.

Have you used a 3D printer before? What was your first project? Let us know in the comment section below.

Recent Comments