What to expect when designing a new idea.

There are a specific number of steps used in the product development process. We will narrow down each step here, explaining it simply and concisely but also outlining the different unforeseen challenges that may require design modifications along the way.

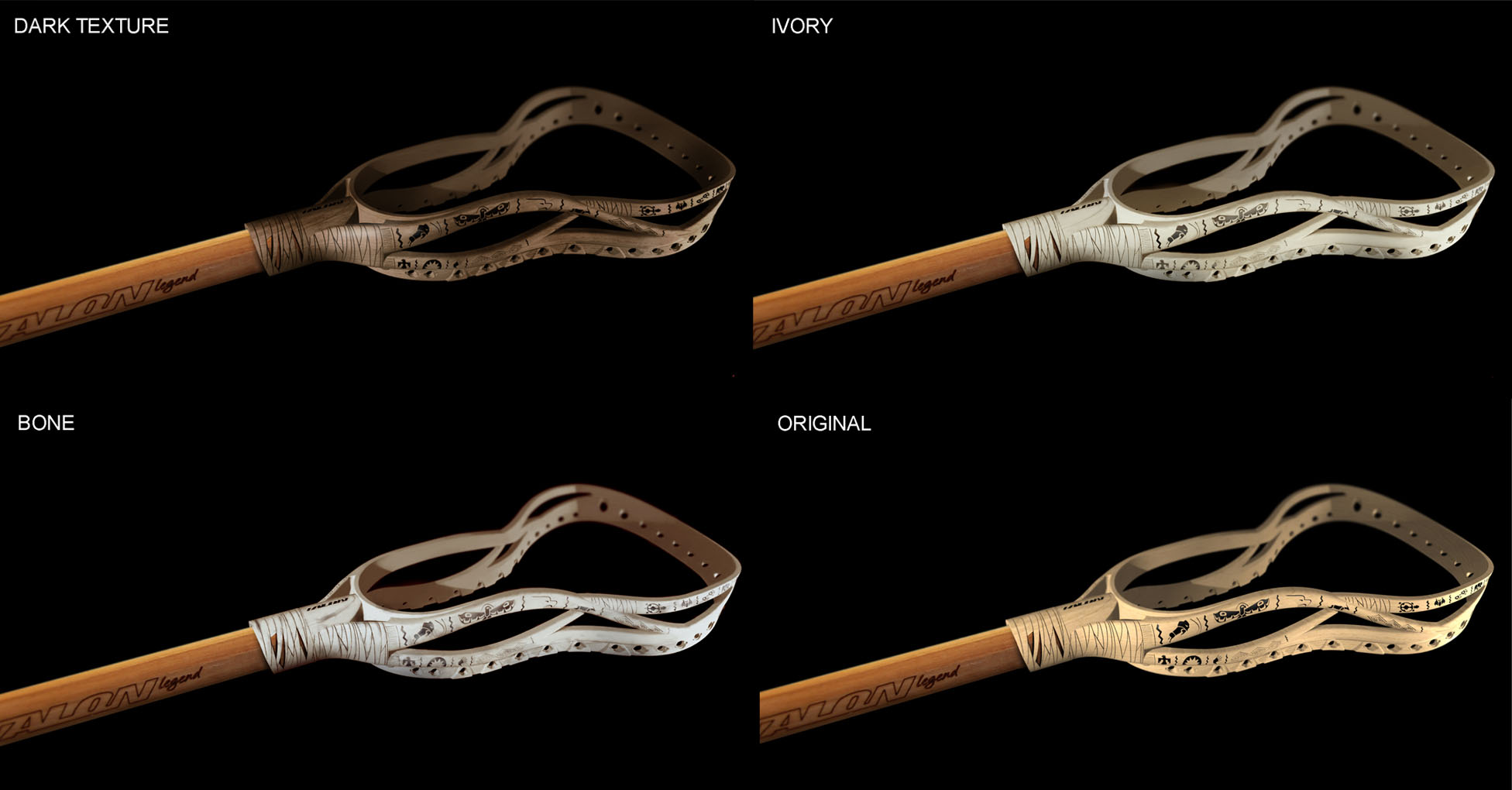

Concept and Sketches

When you visit a design firm the first thing you will discuss in terms of product development is your concept. At Spark Innovations, we will build upon your idea, merge ideas, and evolve your idea into viable product concepts that provide solutions to meet the needs of the end user, the client, and the manufacturer.

Sketches will be created quickly in the interest of expressing and developing your concept. The industrial designers at Spark Innovations use sketching as a process of rapid visualization that allows them to express and document successive ideas almost as quickly as they are thought of. We will provide a few concepts in either sketches or renders. We need detailed information from you to ensure the sketches are as accurate and complete as possible. If you are vague when explaining your design idea, it can be interpreted in different ways and will affect the accuracy of the sketches.

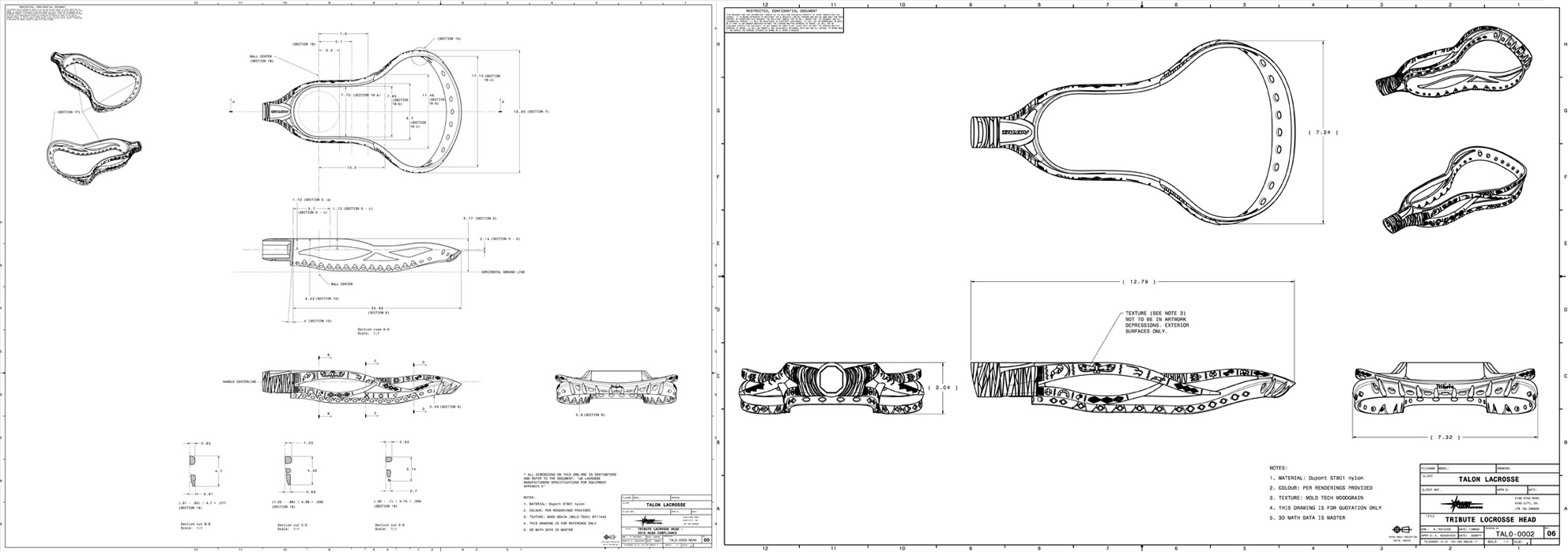

2D/3D CAD Model

Once you approve a specific concept we will refine a more formal drawing to convey your idea. This phase usually takes place on a 3D CAD program such as Solid Works or Catia V5. The important thing to note here is that what you see on paper doesn’t always work in the real world, so expect slight variations from what you saw in the sketches.

Don’t be disappointed; this is normal. Our mechanical engineers have to make sure that each part of the design is ready to prototype in order to work on it quicker for changes you may need. During the modelling process you may not be in 100% agreement with what our engineers have done for you. In order to ensure you are completely pleased we work with you to make the necessary viable tweaks.

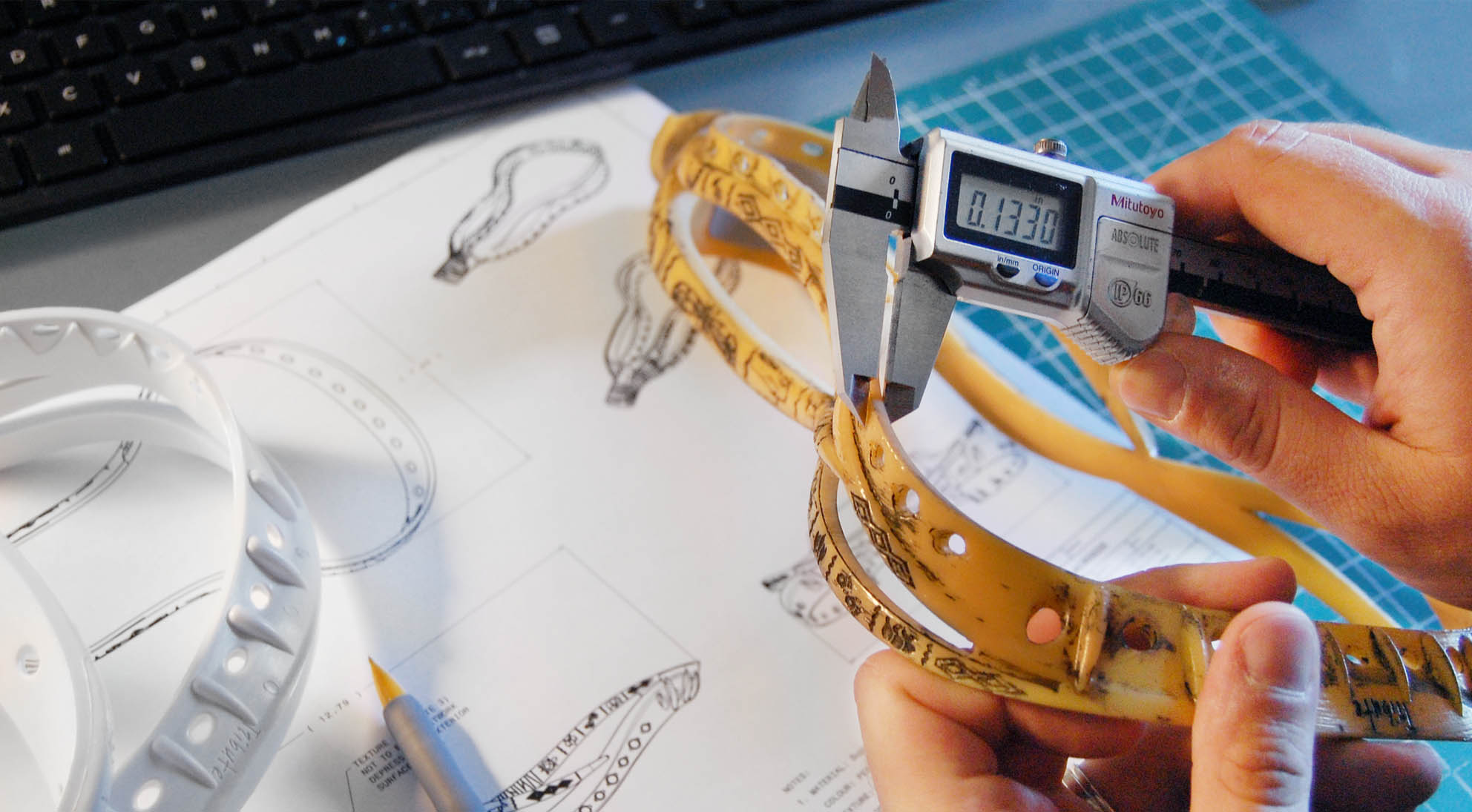

3D Prototype

During the prototyping process at Spark innovations we use our state of the art Objet30 3D Printer to print out your model. This is one of the most exciting moments of the design development process: you actually see your idea come to life.

Here you get to hold it and feel it and discover the ergonomics of the product! Remember that prior to this process you had only seen your idea as a 3D digital concept and were only able to imagine how it would feel. Once it takes physical form, there may need to be slight changes carried out, once, twice or more. As part of this process, our mechanical engineers have to make changes and 3D-print your model again to make sure you are satisfied.

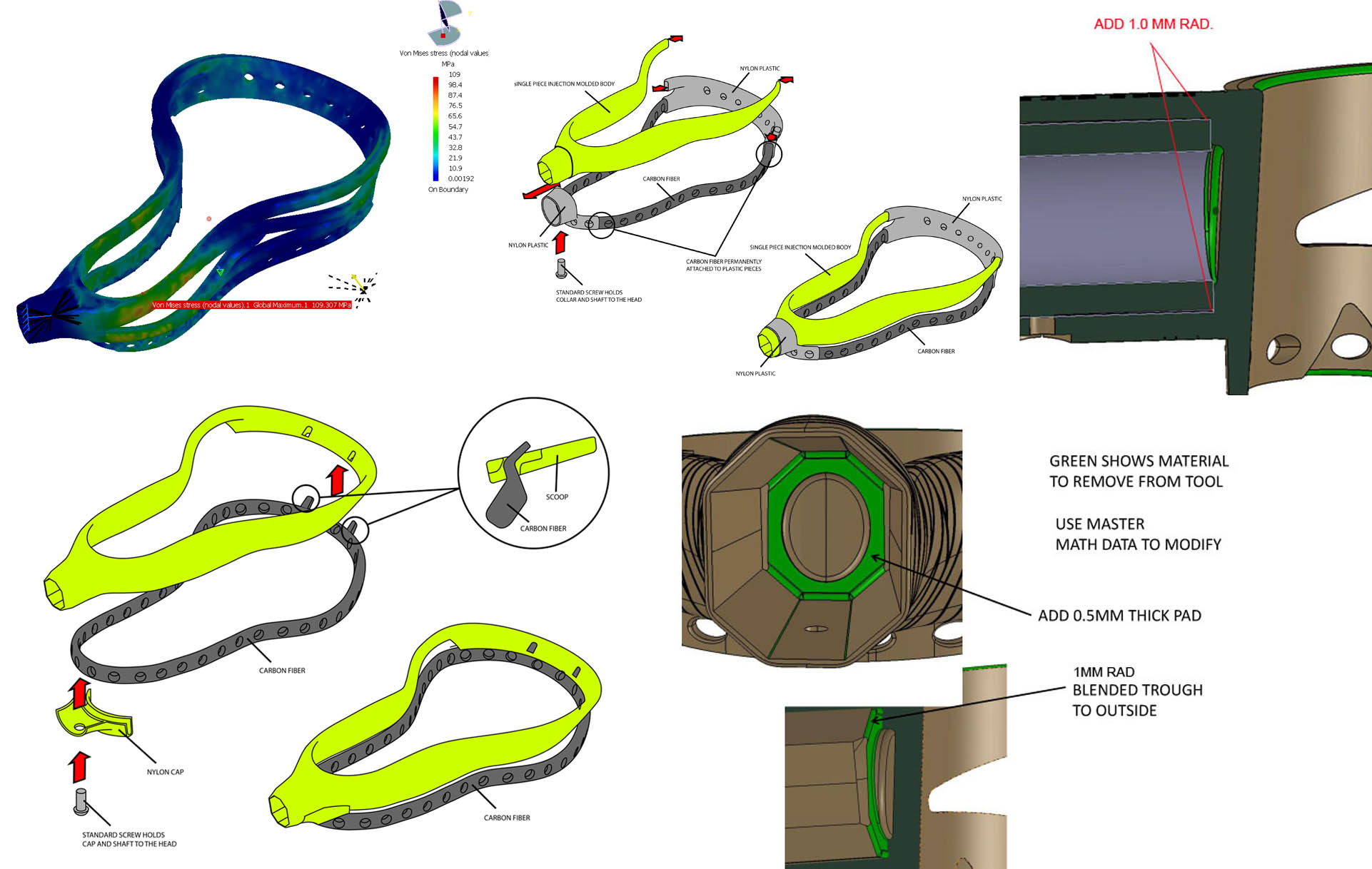

Moulds for Manufacturing

Once the 3D model is ready to go, it’s not really ready to go. We may still encounter a lot of unforeseen challenges. During the development of the 3D model the mechanical engineers made sure you had a prototype that would be easy to tweak and ready to print, but once you are ready to manufacture they have to go back to their CAD drawing and make a production intent design that is manufacturable. At this point they look into details like wall thickness, drafts, steel safe conditions, tolerances, and material selection. Because this is the most crucial part of making your idea come to life, this phase takes a lot of time. This level of detail will be reflected in the moulds that will generate each of the parts of your idea.

Once this moulding process is complete, the CAD is sent to several manufacturers for quotes. You will choose the quote that best suits your needs and expectations. Once you make a decision, we typically send the manufacturer some samples (of course we have to pay for shipping) so we can verify even more details of the existing parts. Even after we have the parts there can still be unexpected issues to resolve. This is very common and takes still more time. Expect multiple communications back and forth between our team and the manufacturer’s team and sending several sets of samples until the product is finally ready to go!

And when we say ready to go we mean ready to manufacture, but before that can be done there is a patenting process, packaging design, marketing and sales…. so much that we can’t cover it all here. Check out this blog for the next steps!

Happy designing! Enjoy!

Recent Comments